Plants need electrical energy without disturbances and interruptions. In order to ensure safe plant operation, our employees perform outstandingly. From planning and construction to maintenance and servicing, they ensure that plants can be operated at full power. We are therefore pleased that our employees enjoy an excellent reputation and are among the best in our industry.

I&C

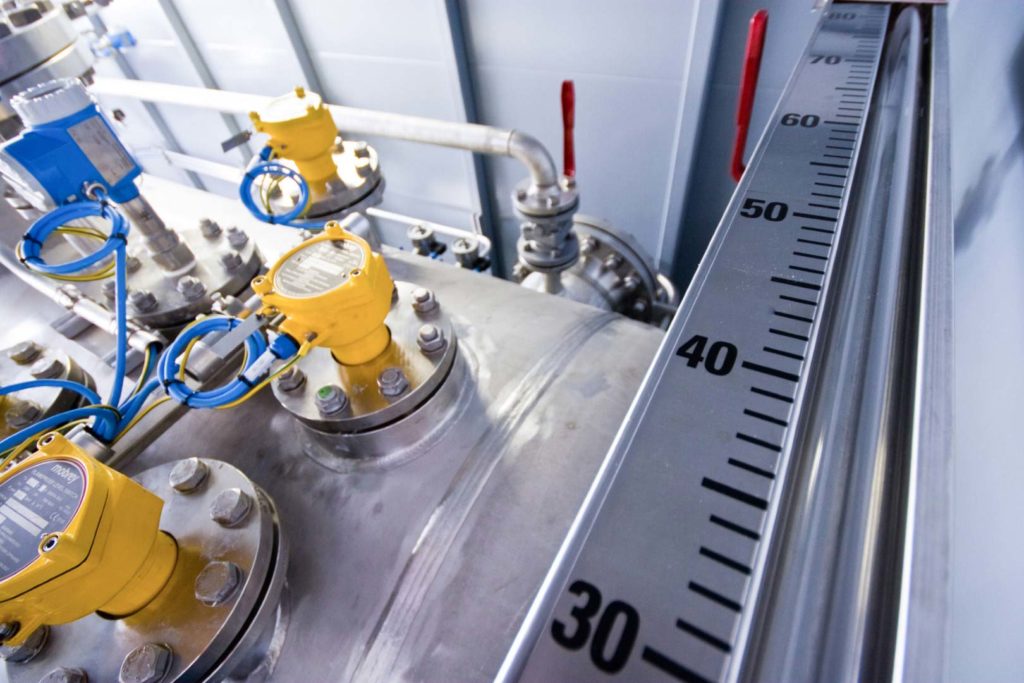

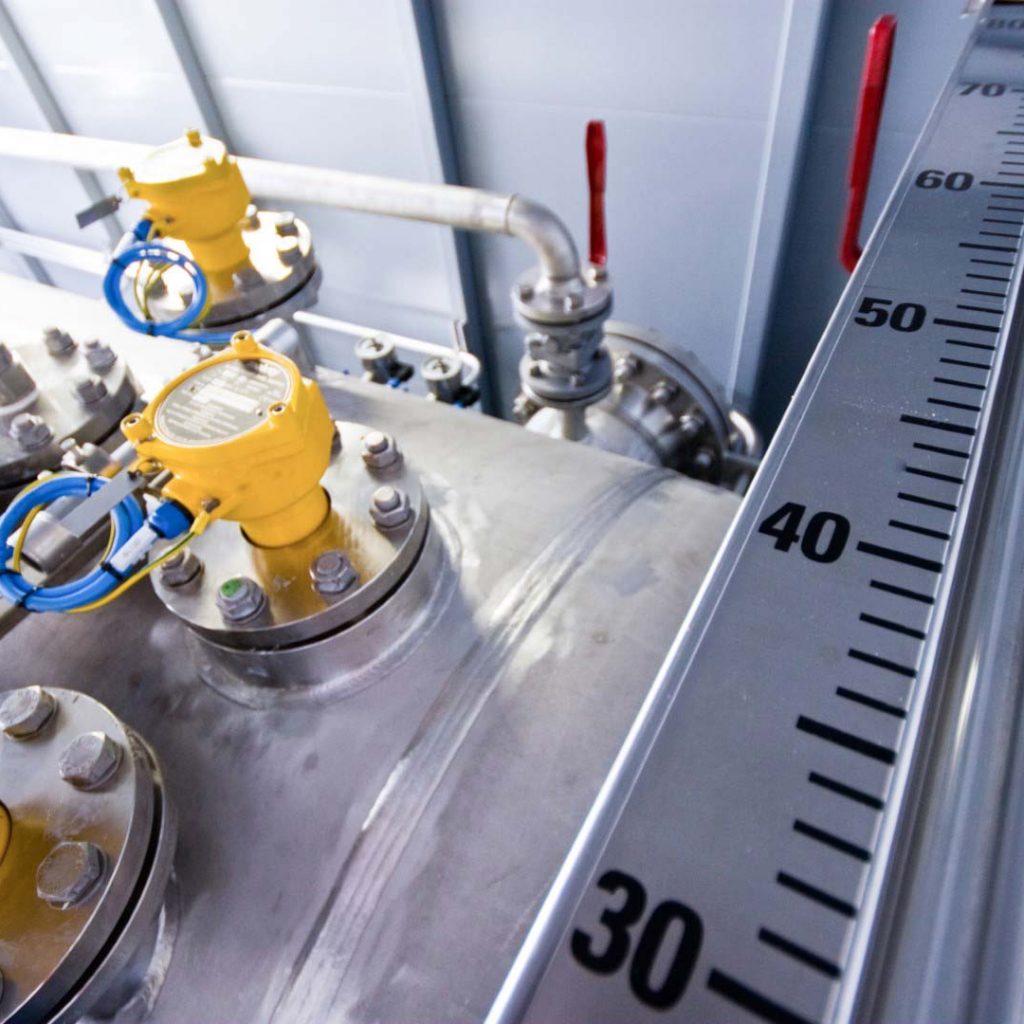

MV systems, LV systems or standby power systems. Our services in the area of power engineering comprise all the essential process steps and work steps from projection and detail planning, the necessary installation, connection technology and wiring up to commissioning and documentation.

I&C

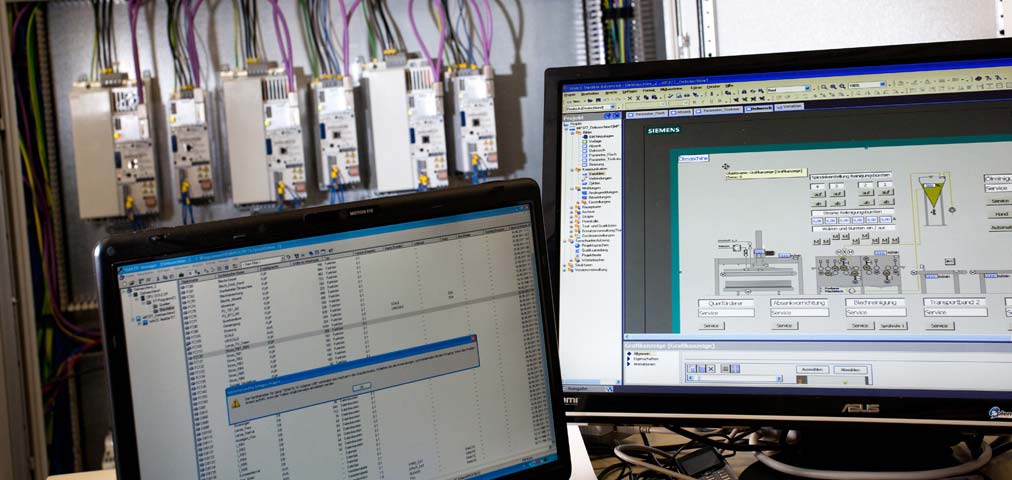

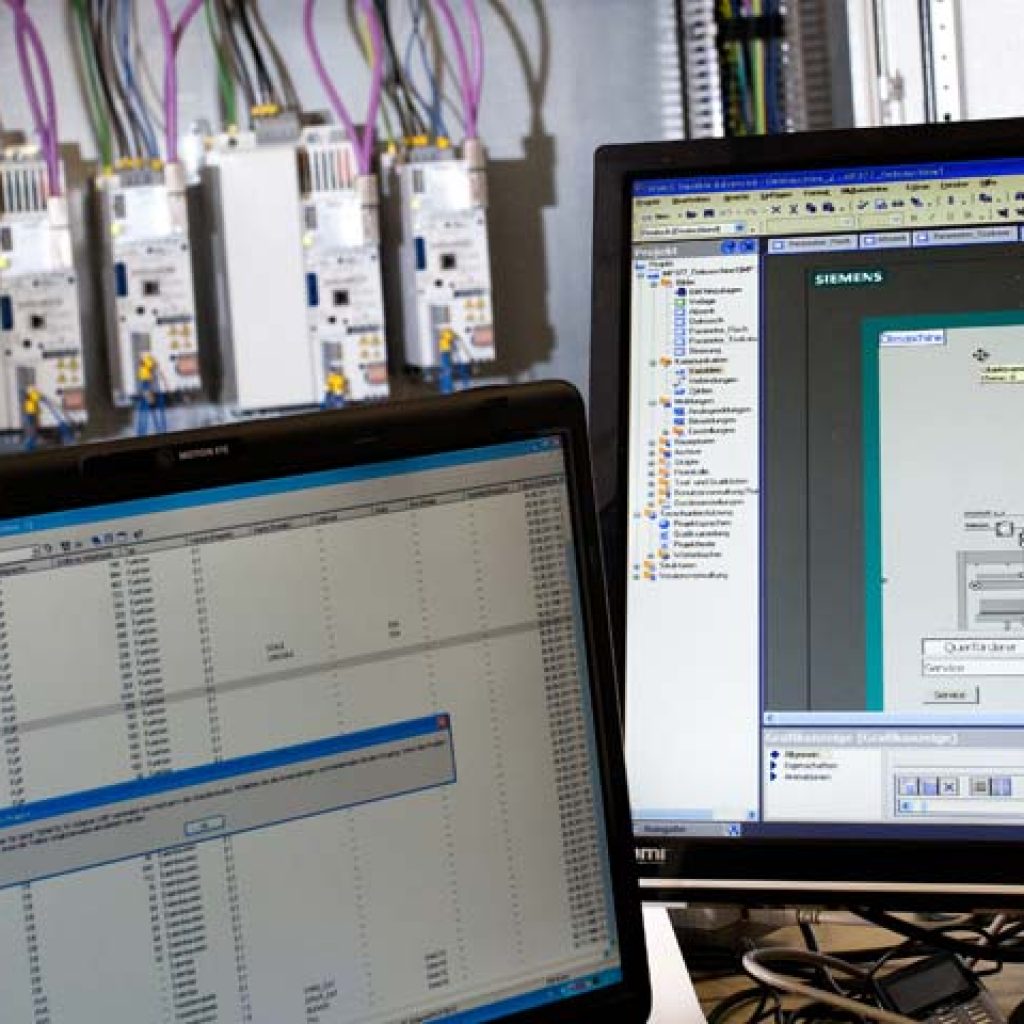

Automation control engineering that is convincing. In our concepts, we combine our versatile know-how of electrical I&C into optimum system solutions. From projection and detail planning with all the concomitant procedures up to installation, commissioning and documentation, we support you in the entire life cycle of your plant.

I&C

I&C engineering for industrial plants has to meet special challenges in the area of safety and performance. Hence, for example, installations in explosion-susceptible areas require a lot of experience and solid know-how, from projection and detail planning up to installation, commissioning and inspection.

I&C

Industrial and production plants, administrative centres or traffic installations. They are all characterised by higher levels of technology and availability as well as marked customer-specific requirements. We are able to surmount all these challenges because we supply the projection, detail planning, installation, documentation and testing of building equipment from a single source.

I&C

Clearly defined maintenance processes as well as services, and regular inspections and maintenance procedures are of decisive importance for fault-free operation of plants. If technical faults occur nonetheless, we are your reliable partners for fast and sustainable rectification of problems.

Kremsmüller has successfully completed a challenging project on the Burghausen campus: the new laboratory container facility for Rosenheim Technical University was completed on schedule and provides additional space for teaching,

Highest safety was the focus of the demanding technical work Norske Skog is entering the packaging paper segment, also known as containerboard. As Gert Pfleger, company spokesman for Norske Skog

Used plastic is a valuable raw material. Upcycling plants from MAS – Maschinen- und Anlagenbau Schulz GmbH make it possible. For this, the company relies on the services of Kremsmüller-I&C

| Cookie | Type | Duration | Description |

|---|---|---|---|

| cookielawinfo-checkbox-necessary | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Necessary". | ||

| cookielawinfo-checkbox-non-necessary | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Non Necessary". | ||

| CookieLawInfoConsent | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the summary of the consent given for cookie usage. | ||

| viewed_cookie_policy | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

| Cookie | Type | Duration | Description |

|---|---|---|---|

| _ga | persistent | 2 years | Used by Google Analytics to distinguish users. |

| _gat | persistent | 1 minute | Used by Google Analytics to throttle requests. |

| _gid | persistent | 24 hours | Used by Google Analytics to distinguish users. |

| AnalyticsSyncHistory | third-party | 30 days | |

| bcookie | third-party | 2 years | |

| lang | third-party | ||

| li_gc | third-party | 2 years | |

| lidc | third-party | 1 day | Saves performed actions on the website. |

| lissc | third-party | 6 months | |

| SalesViewer | |||

| Smartlook | third-party | ||

| UserMatchHistory | third-party | 30 days |