Precision in stainless steel: Two top-class heat exchangers manufactured

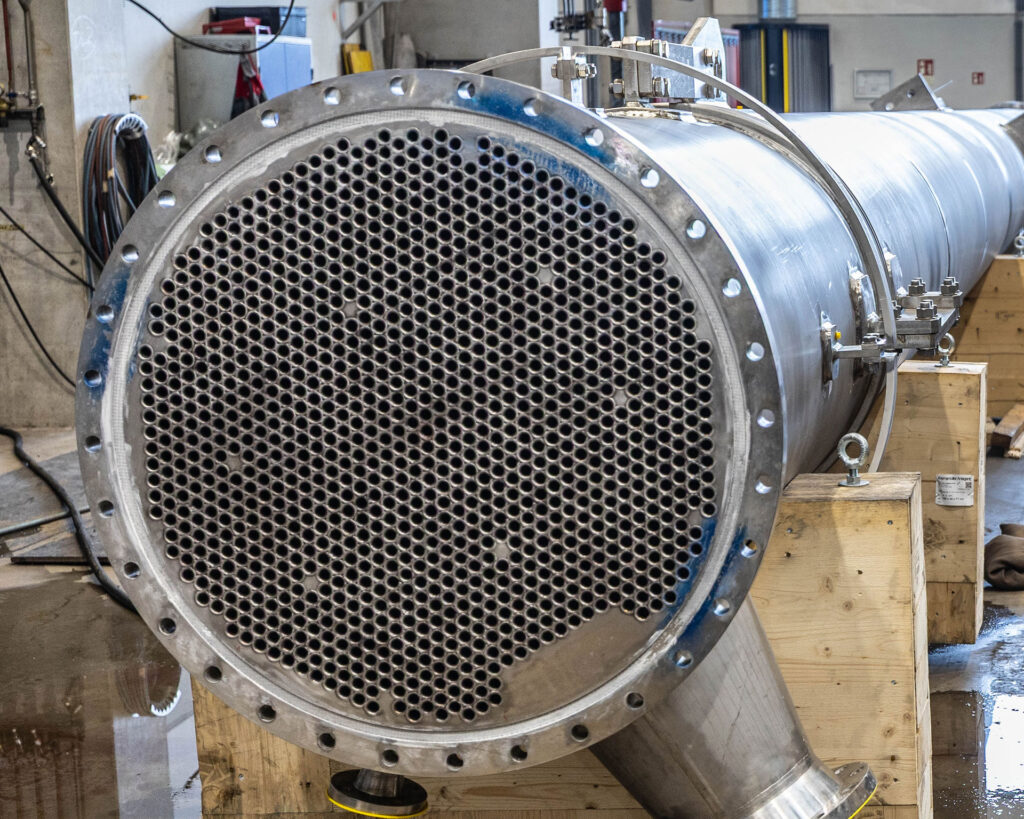

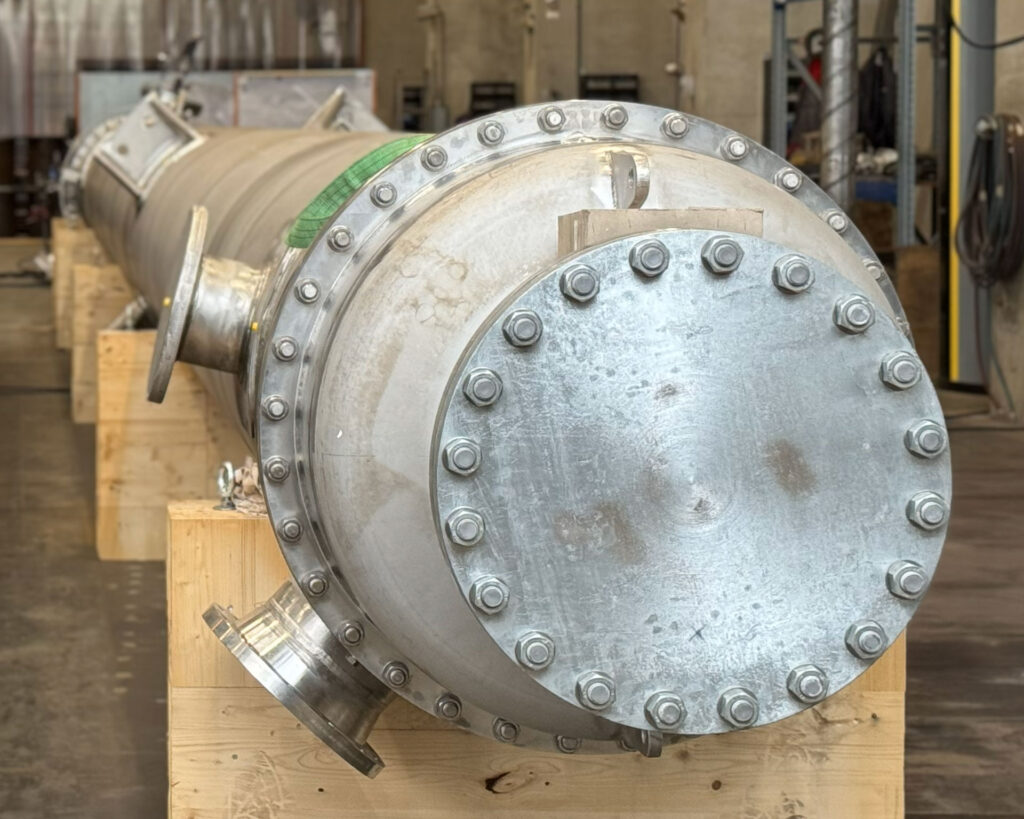

With an impressive length of 19 meters, shell and tube heat exchangers were recently manufactured from 1.4404 stainless steel. Each of the heat exchangers contains just over 1000 tubes – a project that required the highest precision and technical expertise.

The entire design and construction was carried out in-house at Kremsmüller – precisely tailored to the customer’s requirements. The implementation was carried out with the utmost care and technical excellence – from planning to final production.

Special attention was paid to the precise processing of the tube bundles. Threading the more than 1,000 tubes per heat exchanger required not only dexterity, but also a well-coordinated team.

With this project, Kremsmüller once again underlines its expertise in the manufacture of sophisticated equipment – and with impressive results.

Heat exchangers are technical devices that transfer heat from one medium to another without mixing the media. They are essential for numerous industrial processes, for example in the energy, chemical, and food industries, and must meet the highest standards in terms of materials and workmanship.

More posts by Kremsmüller

Working in high mountains: planning and experience are crucial

Projects in high mountain regions require more than just technical expertise. They demand courage, perseverance, and particularly careful preparation. It is precisely in these locations,

Kremsmüller supplies electrical engineering solution for university campus

Kremsmüller has successfully completed a challenging project on the Burghausen campus: the new laboratory container facility for Rosenheim Technical University was completed on schedule and

Two top-class heat exchangers manufactured

Precision in stainless steel: Two top-class heat exchangers manufactured With an impressive length of 19 meters, shell and tube heat exchangers were recently manufactured from

Tank farm: Technical precision over 750 meters of pipe length

Leikermoser Energiehandel relied on Kremsmüller’s technical expertise for the construction of a new tank farm in Hallein. The project involved complex pipework, precise surface finishing,

Successful project completion in the Tyrolean high mountains

Successful project completion in the Tyrolean high mountains In the first project report, we already provided detailed information about Kremsmüller’s high-altitude construction site in Schranbach

Work and hope: Kremsmüller For Life supports people with cancer

With the “Kremsmüller For Life” initiative, the company emphasizes the importance of social commitment. Under the motto “Work for All,” sustainable projects were specifically sought