Kremsmüller

Founded in 1961, the Kremsmüller Group employs a staff of nearly 1,700 and continues to be family-operated to this day. The company’s headquarters are located in Steinhaus near Wels in Austria. Subsidiaries and branches have been established in Vienna/Schwechat (AT), Ploiesti (RO), Chemnitz (DE), Maribor (SLO), and other locations. In addition, Kremsmüller operates a variety of service support points with long-standing industrial customers. The staff in the employ of Kremsmüller use their expertise, experience and craftsmanship to keep the production facilities of important industrial sectors running smoothly.

Process technology

Since 1961 Kremsmueller stands for premium quality in industrial plant construction. The family-run company has made versatility to a business principle over those years. From pipeline, tank and apparatus construction to hard and software engineering – our long established company provides all services from one source. Without a doubt, the experiences over decades and the wide range of expert knowledge, are playing a central role at Kremsmueller. In order to better meet the customer and market requirements, our company has further developed in its technical know-how.

Kremsmueller has now established itself in the process technology sector and therefore we are able to serve an even wider range of products. This includes apparatuses and plants like thin-film evaporators, thin-film dryers, evaporation plants and much more. In this field, Kremsmueller offers a wide range of applications in its own in-house technical center. From feasibility studies to laboratory and semi-technical tests up to sample quantities production. In doing so, we can revert back to decades of experience by our experts.

From the first idea, to project planning and realization up to a trouble-free operation and planned completion of the plant, Kremsmueller takes all project steps from a single source, which is unique in this marketplace.

Products and services

The Kremsmueller process technology deals with distillation, evaporation and drying plants. This involves thermal separation processes for the recovery and recycling of residual materials. Our technologies can be found in the following industrial sectors:

- Fiber and pulp industry

- Environmental technology

- Chemical industry

- Milk-processing industry

- Beverage and food industry

- Sugar and starch industry

- Polymer industry

- Petrochemical sector

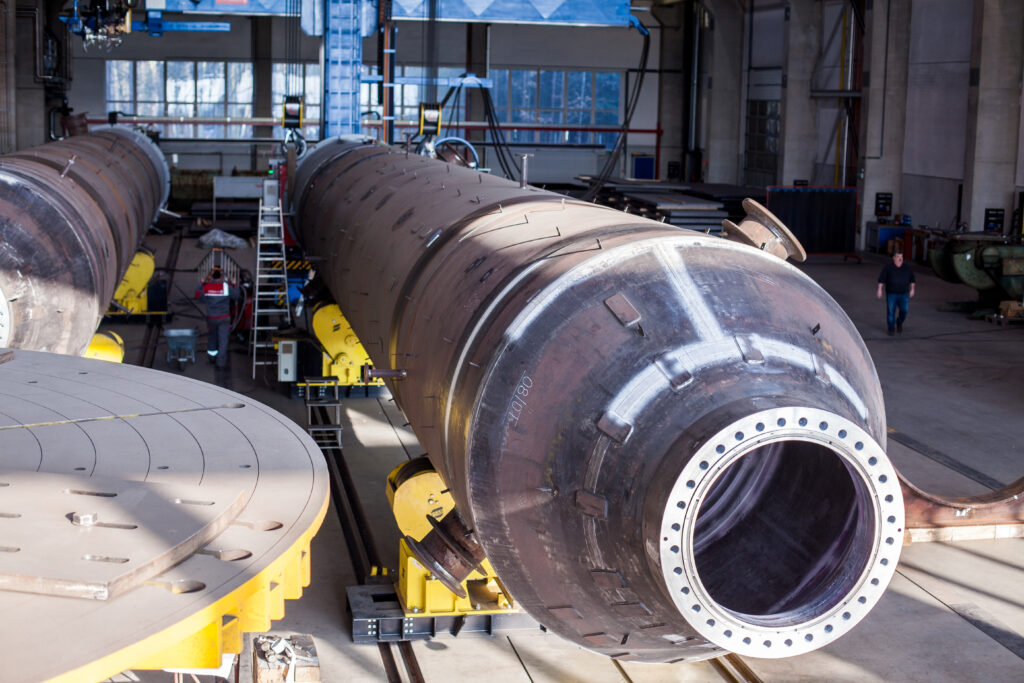

Product overview in apparatus construction

Our product range spans across a variety of specialized apparatuses and tanks designed for various industrial applications. Each product embodies superior quality and precise workmanship.

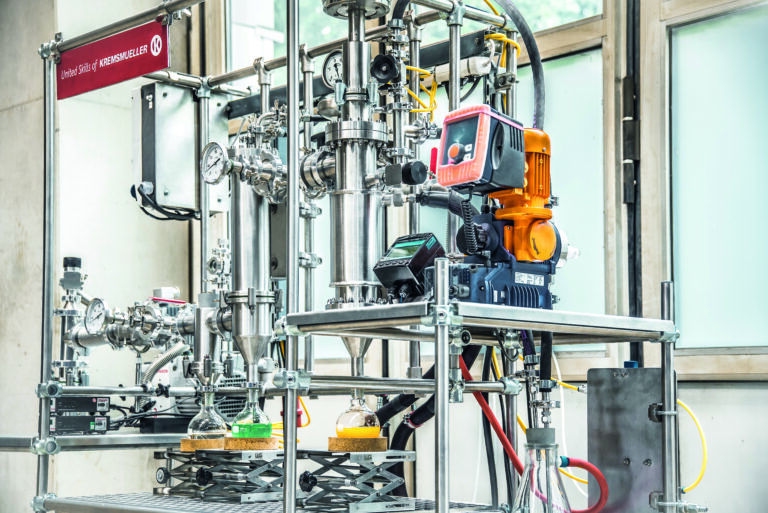

Kremsmüller Test Center

Focusing on energy efficiency and environmental friendliness, the Kremsmüller Test Center provides a top-tier platform for the development of sustainable solutions in various industries. We utilize our expertise and advanced facilities to lend you our support in realizing your visions for an environmentally conscious future.

Enter into the engineering phase at no risk.: Before you make large investments in a process plant or equipment, we test your products under the process parameters you specify. This allows you to form an overall perspective of your planned project and, thus, the best conditions for the start of the scale-up process. Consequently, you can initiate further project steps and engineering phases without transfer risk.

We go a crucial step further: We know that you as a customer attach vital importance to the economic efficiency and feasibility of your projects. This is exactly why we start focusing on these goals from the word “go”. We go above and beyond the services rendered by conventional research institutions. Our expertise in apparatus construction lets us factor in your future overall system as soon as we receive your initial request. Not only do we offer you key figures, consumption numbers and information on the theoretical feasibility, but we also analyse the economic aspects and the actual feasibility of your undertakings. The assistance we lend you will not only let you realise your project, but will also turn it into an economic success. We always keep a firm eye on your overall system.

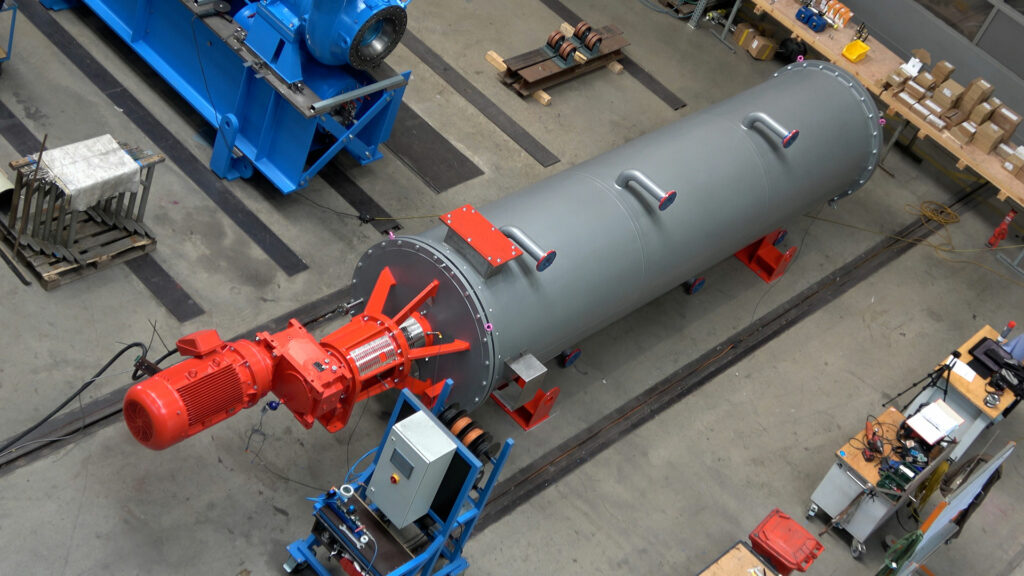

Sewage sludge dryer for Suez in Yangzhou, China

For a sewage sludge incineration plant in the Chinese city of Yangzhou, Kremsmueller supplied two thin-film dryers, each with an area of 50 m². Each dryer can dry 5 tons of pre-dewatered sewage sludge to 2.2 tons, increasing the degree of drying from 20% to 46%. The sewage sludge can then be incinerated in fluidized bed furnaces without additional energy. The energy from the incineration process is also recovered and used.

Experience our products in life size with augmented reality

Mitarbeiter

Your contact persons

Head of process engineering machines

+43 7242 630-1504

Head of Sales Process Engineering Machines

+43 7242 630-1526

Sales, Marketing & Communication

+43 7242 630-1400