Spectacular repair work

A vacuum can release tremendous amounts of energy. Kremsmueller was entrusted with eliminating the spectacular traces of a “negative pressure incident.”

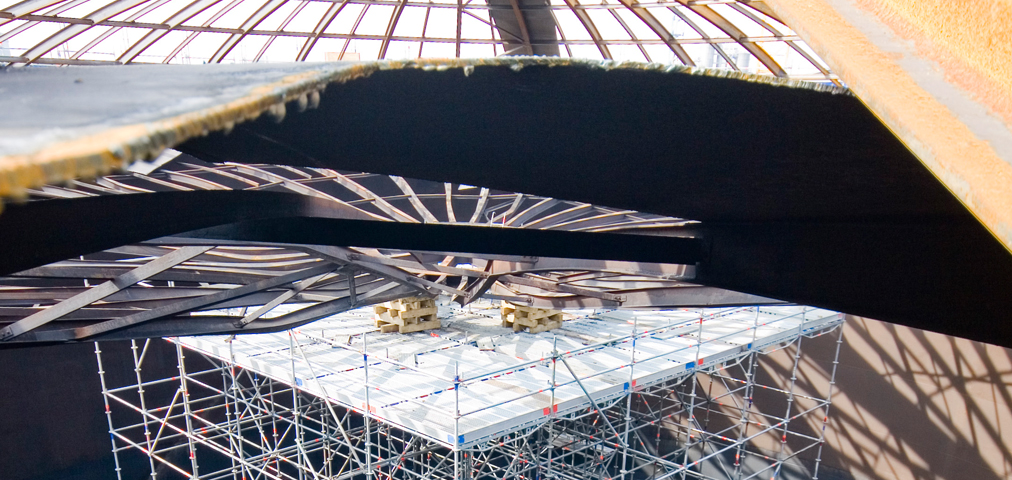

This involved the roof of an oil tank. After decades of operation, the filter screens of the venting lines were completely clogged with oil deposits. This layer was thick enough to cause a powerful negative pressure to be created – so strong that the 43 meter roof of the tank had been sucked in no less than 8 meters.

At the same time the old roof was dismantled, a substructure for the new one was installed. Especially the “sliver-by-sliver” disassembly of the battered sheet sections and steel girders was planned down to the last detail: A maximum level of safety had to be continuously ensured for the installation team. Any uncontrolled collapse of parts could have damaged the sensitive heating equipment at the bottom of the tank. The old and new roof were supported by a high-strength supporting frame measuring 12x12x20 meters.

Adverse weather conditions often degrade the quality of welds. An elaborate weather-protection structure deflected the wind from the tank roof and thus ensured 1,000 running meters of first-rate welds.

With this project, Kremsmueller’s experts once again demonstrated their universal talent: The completely new piping, a new sprinkler system, and protective structures rounded out the 120 tons of installation weight.

If you would like to find out more about this project, click on the “Contact” button on the right to reach the experts directly.