Rings for South America

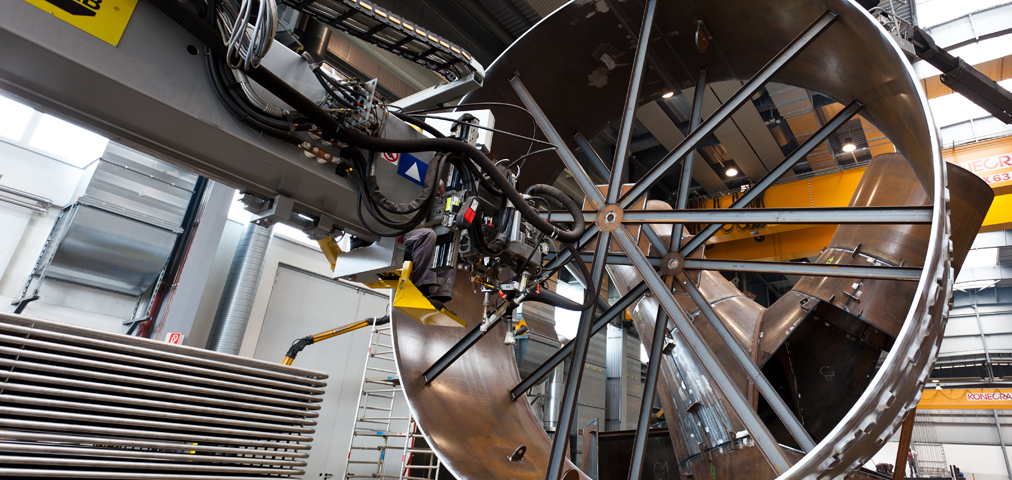

Four raceway segments with a diameter of over 5 metres were manufactured to custom fit.

The rings, made by the tank construction and production department, are to be mounted on a dryer drum of a metal mine in Venezuela. The aspect of significance was the fact that the baffle plates had to reach into an existing raceway. The challenge here: the accuracy of the fit between new and old. The customer, a leading cement manufacturer in the world market, placed a great deal of emphasis on maintaining the narrow tolerances. Thus, the gusset plates, when welded, could not vary even a half millimetre from the desired value.

The project leader and his team did not disappoint the customer: the gusset plates matched perfectly. The auxiliary constructions inside the rings ensured that the rings withstood the long transport across the Atlantic undamaged and remained absolutely round. The Kremsmueller material inspectors approved the impeccable quality of the weld seams.

Would you like to know more about this project? Please click Contact at the top right and the experts from Kremsmueller will happily provide information.

The project leader and his team did not disappoint the customer: the gusset plates matched perfectly. The auxiliary constructions inside the rings ensured that the rings withstood the long transport across the Atlantic undamaged and remained absolutely round. The Kremsmueller material inspectors approved the impeccable quality of the weld seams.

Would you like to know more about this project? Please click Contact at the top right and the experts from Kremsmueller will happily provide information.