Pioneering work at our very own doorstep

The biggest-ever stainless steel drinking water tank is located in Steinhaus. Nonetheless, the concept had to establish its superiority over international competition.

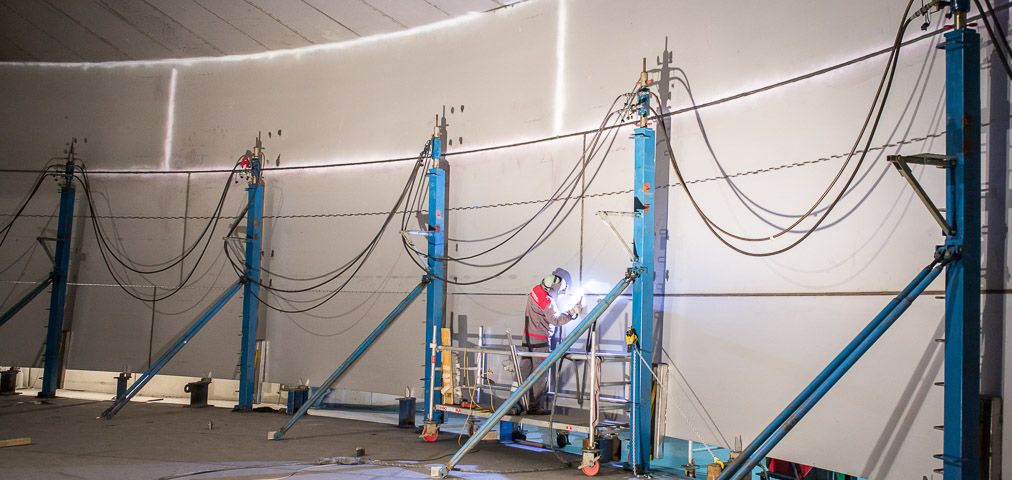

The tank, with its diameter of 28 metres and height just under 9 metres, holds no less than 5000 m³ of spring water. For the first time ever, such a large tank was fabricated in stainless steel – and not, as is usually the case, underground and of concrete.

That the project would be awarded to Kremsmueller owing to the proximity of the manufacturing facility was not to be taken for granted at all. In fact, Kremsmueller demonstrated its superiority over the international competition with a convincing concept. A lean-duplex material that was perfectly customized to the local drinking water was used.

Would you like more information? Click on Contact and you will be put directly in touch with our experts with an email.

That the project would be awarded to Kremsmueller owing to the proximity of the manufacturing facility was not to be taken for granted at all. In fact, Kremsmueller demonstrated its superiority over the international competition with a convincing concept. A lean-duplex material that was perfectly customized to the local drinking water was used.

Would you like more information? Click on Contact and you will be put directly in touch with our experts with an email.