Optimizing production processes

Kremsmueller Industrieanlagenbau has provided an international firefighting equipment company with more efficiency. Flexible and environmentally safe – these were the requirements for the new pump test stands.

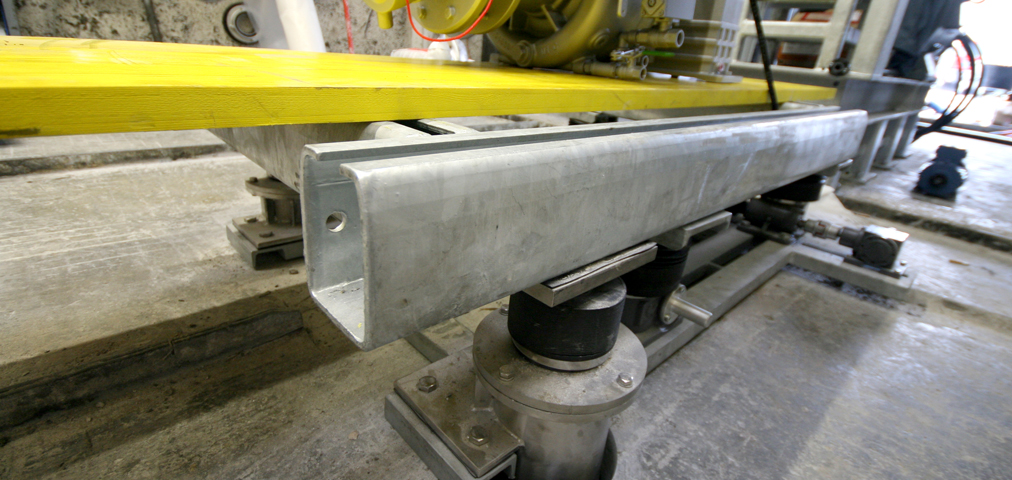

Flexibly adjustable elevating platforms were planned, fabricated, and installed to enable testing of pumps of all types and sizes. Using a spindle drive, the lift height is continuously adjustable while allowing a load capacity of up to 2 tons. A 1,200 kg steel structure was constructed to provide solid anchoring in the concrete floor.

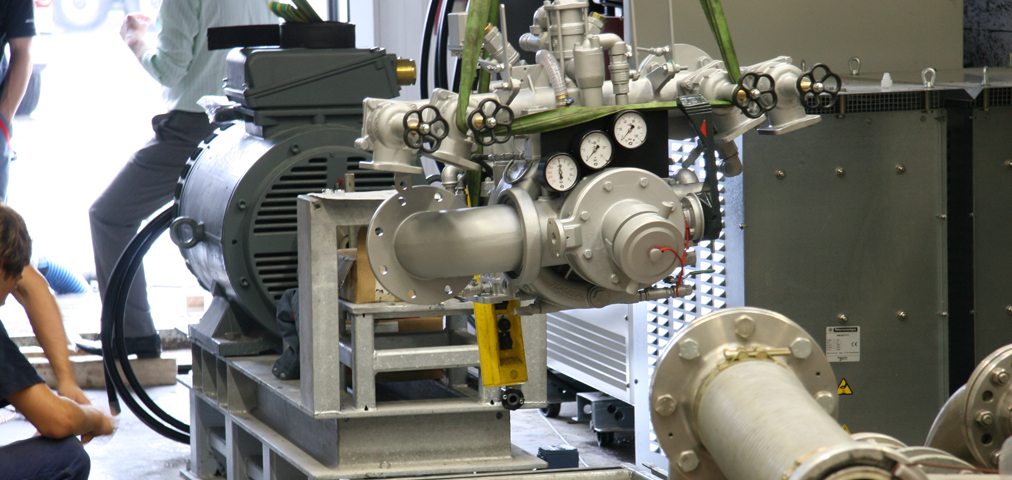

The outdated diesel drive system was replaced by an electrical drive. Based on the high power requirement, Kremsmueller’s electrical experts installed a 10 kV transformer. Transformation of this area into an electrical service room including grounding system, safety guards and barriers ensured the required level of safety. An optimal supply of power was now ensured by 220 meters of 10 kV cabling, running in part underground, including transformer compartments and five fire barriers. The requisite incoming feeder unit together with frequency converter and drive motor, as well as metering shafts to measure speed and mechanical output, were also installed.

Testing over the entire speed range of 0 to 4,500 revolutions per minute, as well as a simple change-over from clockwise to counterclockwise rotation is now possible.