Operation on a lifeline

Austrian crude oil supply in the hands of Kremsmueller

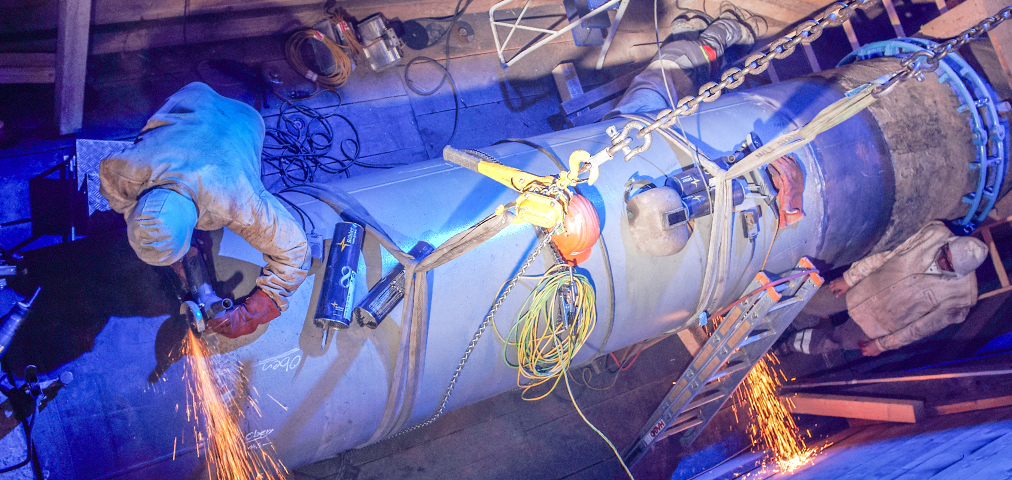

The renovation of some segments of the pipeline that carries 90% of the Austrian crude oil requirement was preceded by months of planning and organisation work – not least, because coordination was required with the refineries… This was because the crude oil flow had to be stopped completely for 80 hours.

Within these 80 hours, the specialists of Kremsmueller got to work. Before starting the work, a five kilometre-long segment of the pipeline had to be emptied into a relief tank. Every action was meticulously planned.

The pipeline was broken down into its individual sections by pipe milling. For safety reasons, the pipe was flushed before starting work. Nonetheless, this cold cutting method was used to ensure that no there were no sparks. Any gas residues that remained were thus rendered harmless.

Thereafter, the parts to be replaced were fitted correct to the nearest milimetre. For weld seams of two to three metres, the Kremsmueller specialists needed four hours each. The weld seams were then inspected right away at the site itself by an independent agency. The result: Perfect quality work that was delivered exactly on schedule.

Built in the 60s, the Transalpine oil pipeline transports about 35 million tonnes of crude oil from Triest via the main Alpine ridge to Ingolstadt. To transport this gigantic quantity by road would have taken approximately 8000 tankers per day.

Would you like to know more on this project? Please click at the top right on Contact and you can reach our pipeline construction experts directly.