It’s hot!

How do steel works remain competitive? With optimum energy efficiency!

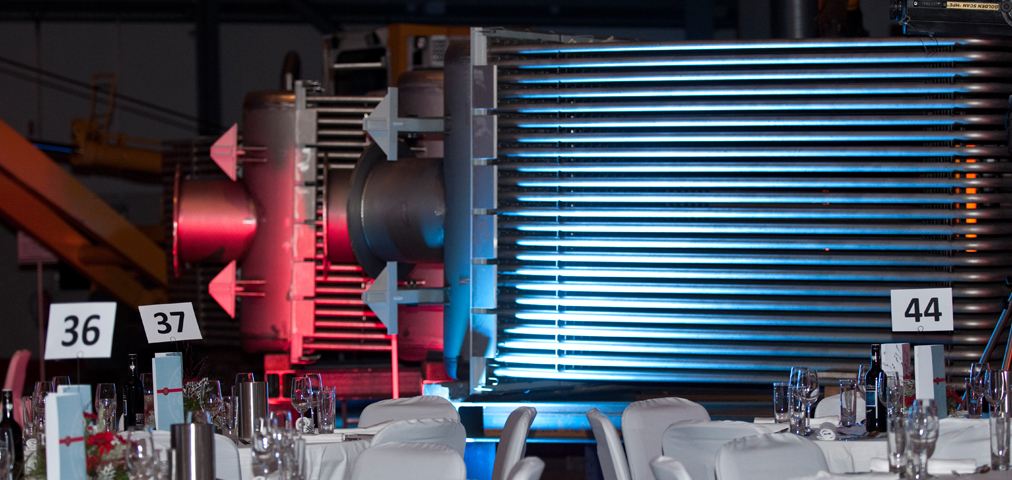

Last autumn, Kremsmueller manufactured eight U-tube heat exchangers for a plant in Venezuela. The plant produces steel using gas – through direct reduction of iron oxide (MIDREX process). Exhaust gases with temperatures of up to 1000°C are generated during the reactions. The energy of the exhaust gases is re-used and transferred from the exhaust gas to the reduction gas in heat exchangers manufactured by Kremsmueller.

Since the wear of the machines is considerable owing to the heat and the aggressive exhaust gases, the working of the heat-resistant material was a particular challenge for the Steinhaus-based workshop team. A total of 3312 pipes were welded in Steinhaus using the orbital welding process. Thanks to process optimisation, it was possible to significantly minimise the warpage of the perforated plates.

Are you interested in the project? Click on Contact to directly reach our experts.