High-tech for the chemical industry

Kremsmueller manufactures a pressure apparatus for one of Russia’s biggest chemical industry groups

The production of the reactor, which is used for extracting hydrogen from hydrocarbons, was divided into three parts, which was done in collaboration with two other partners from the sector. Kremsmueller was responsible for the manufacture of the pressure apparatus weighing 125 tonnes totally, as well as for the assembly of the individual components.

A special swivelling table fixture was used for welding the hemispherical bottom. It brought the hemisphere into position, so that welding could be carried out using the submerged arc process according to the radius of the hemisphere. The wall thickness of the apparatus is 80mm.

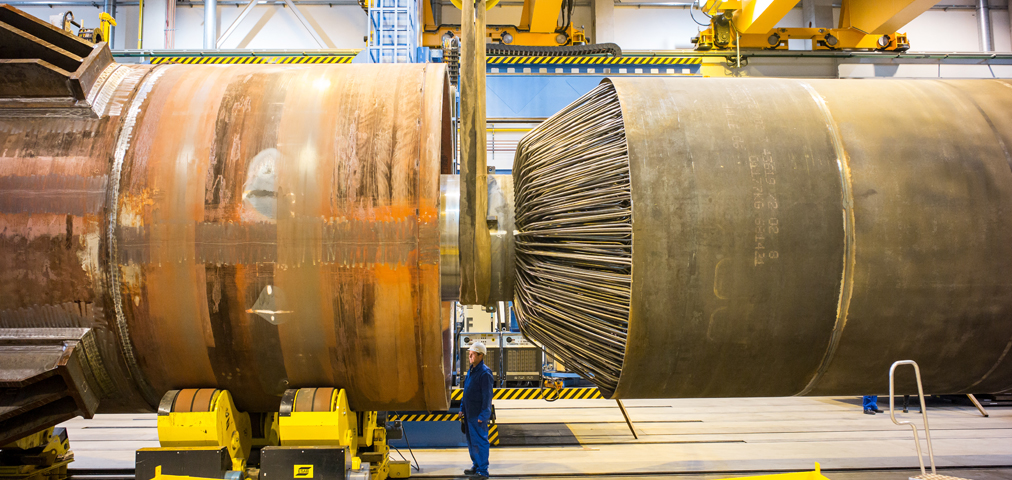

The individual components, a 57-tonne pipe bundle, a 38-tonne steam drum and the pressure apparatus fabricated by Kremsmueller weighing in at 125 tonnes, were brought together in the tank and pressure apparatus manufacturing facility in Steinhaus. The insertion of the pipe bundle in the pressure apparatus was a particularly delicate operation.

With a total length of 24 metres and a diameter of 4 metres, the finished shift reactor weighs 220 tonnes. These were dimensions that were also a challenge for the transport. All the autobahn tunnels were spatially measured with a 3D laser. The transport height of the reactor was 4.88 metres – just about 5cm below the lowest passage height along the transport corridor to the port.

Would you like to know more on the tank and apparatus manufacturing facility of Kremsmueller? With a click on Contact, you will directly reach the experts from the relevant technical division.

A special swivelling table fixture was used for welding the hemispherical bottom. It brought the hemisphere into position, so that welding could be carried out using the submerged arc process according to the radius of the hemisphere. The wall thickness of the apparatus is 80mm.

The individual components, a 57-tonne pipe bundle, a 38-tonne steam drum and the pressure apparatus fabricated by Kremsmueller weighing in at 125 tonnes, were brought together in the tank and pressure apparatus manufacturing facility in Steinhaus. The insertion of the pipe bundle in the pressure apparatus was a particularly delicate operation.

With a total length of 24 metres and a diameter of 4 metres, the finished shift reactor weighs 220 tonnes. These were dimensions that were also a challenge for the transport. All the autobahn tunnels were spatially measured with a 3D laser. The transport height of the reactor was 4.88 metres – just about 5cm below the lowest passage height along the transport corridor to the port.

Would you like to know more on the tank and apparatus manufacturing facility of Kremsmueller? With a click on Contact, you will directly reach the experts from the relevant technical division.