Greater Quality and Efficiency Thanks to New Control Station

Kremsmüller fulfilled all customer requirements when converting the sheet rolling mill for Böhler Bleche

An exciting project for Kremsmüller was the reconstruction of the sheet metal rolling stand for Böhler Bleche in Hönichsberg near Mürzzuschlag, where titanium plates for the aviation industry are manufactured, among other products.

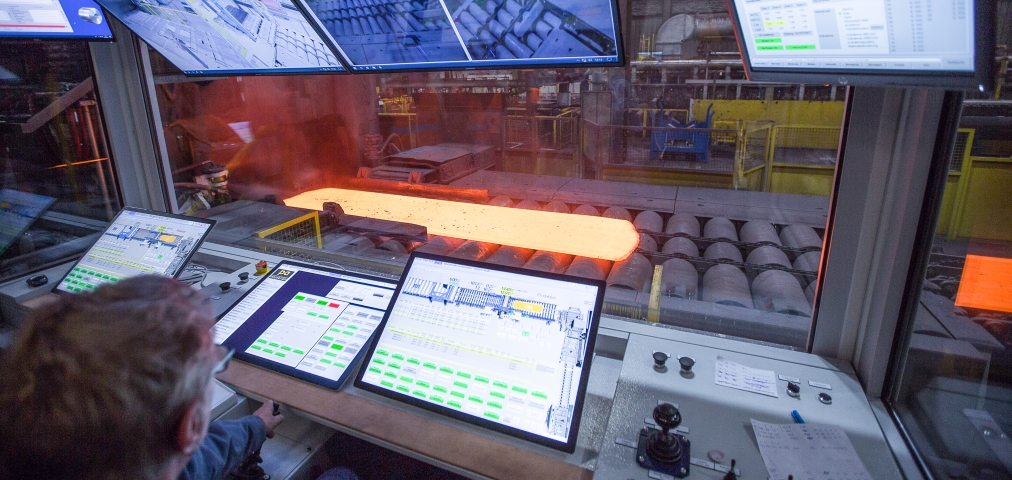

Before the conversion, the sheet thickness had to be measured manually; now it is laser-based. The measurement data are evaluated in a newly installed control station. Our employees of the I & C division in Schwechat were involved in the construction of this control station. Kremsmüller undertook the planning of the entire electrical measurement and control systems, the complete distributor and console production, the installation of the electrical measurement and control systems and the commissioning. The only exception was the main drive.

In this instance, we developed solutions specially tailored to the needs of our customer. In particular, the control panel with the screens was manufactured and installed precisely to the customer’s specifications, and they were highly satisfied with the outcome

Now that the rolling mill has been converted, quality and efficiency can be increased. It is also possible to produce even thicker sheets with still more special properties. Many large media such as Krone, ORF (Austrian Broadcasting Corporation) or the Industriemagazin have already reported on the project. Kremsmüller know-how thus helps companies to continue to be among the best in the world.

Before the conversion, the sheet thickness had to be measured manually; now it is laser-based. The measurement data are evaluated in a newly installed control station. Our employees of the I & C division in Schwechat were involved in the construction of this control station. Kremsmüller undertook the planning of the entire electrical measurement and control systems, the complete distributor and console production, the installation of the electrical measurement and control systems and the commissioning. The only exception was the main drive.

In this instance, we developed solutions specially tailored to the needs of our customer. In particular, the control panel with the screens was manufactured and installed precisely to the customer’s specifications, and they were highly satisfied with the outcome

Now that the rolling mill has been converted, quality and efficiency can be increased. It is also possible to produce even thicker sheets with still more special properties. Many large media such as Krone, ORF (Austrian Broadcasting Corporation) or the Industriemagazin have already reported on the project. Kremsmüller know-how thus helps companies to continue to be among the best in the world.