Batchbin revolutionises the finishing plaster industry

Local dosing technology is in use in a construction materials factory in Brno. For the first time, fine construction adhesives can now also be manufactured.

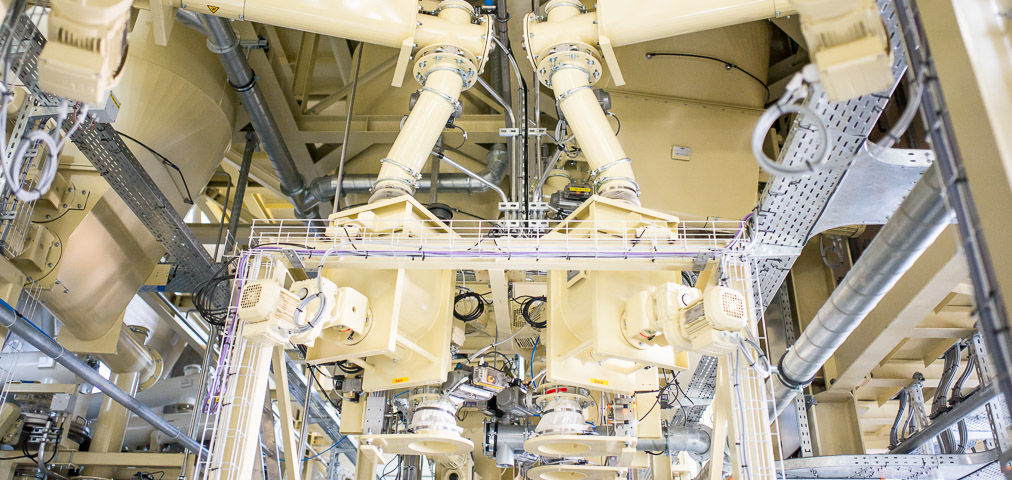

With the award of the contract for the Czech project, an entry was made for the first time in the hard-fought finishing plaster industry. The Batchbin system was able to assert itself thanks to its high flexibility and compact construction. This powder dosing system has been installed over an area of about 10 by 20 metres.

The high accuracy and the modular construction allow production of many different recipes – from coarse finishing plaster to fine finishing cement. The system is also open for future increases in capacity.

The project took six months from the start of assembly to commissioning. Apart from the Batchbin team, the I&C department of Kremsmueller had also been deployed and took care of the automation of the system.

Would you like to know more about Batchbin? If you would, click on Contact (envelope icon) and you will be put in touch directly with our experts.

The high accuracy and the modular construction allow production of many different recipes – from coarse finishing plaster to fine finishing cement. The system is also open for future increases in capacity.

The project took six months from the start of assembly to commissioning. Apart from the Batchbin team, the I&C department of Kremsmueller had also been deployed and took care of the automation of the system.

Would you like to know more about Batchbin? If you would, click on Contact (envelope icon) and you will be put in touch directly with our experts.