Batchbin in the building materials industry

An international producer of building materials was searching for a flexible solution to manage its ever-growing product line. The company found what it needed with Kremsmueller and Batchbin.

An international producer of building materials was searching for a flexible solution to manage its ever-growing product line. The company found what it needed with Kremsmueller and Batchbin.

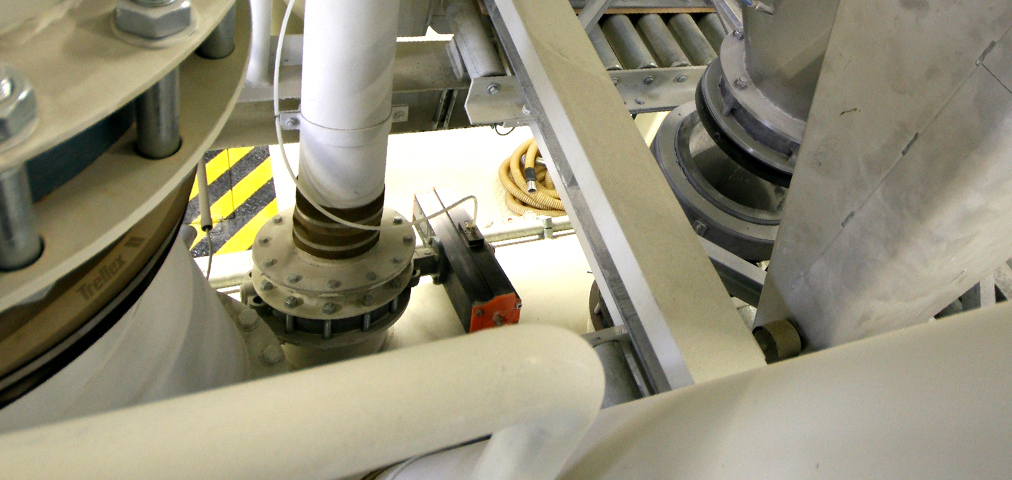

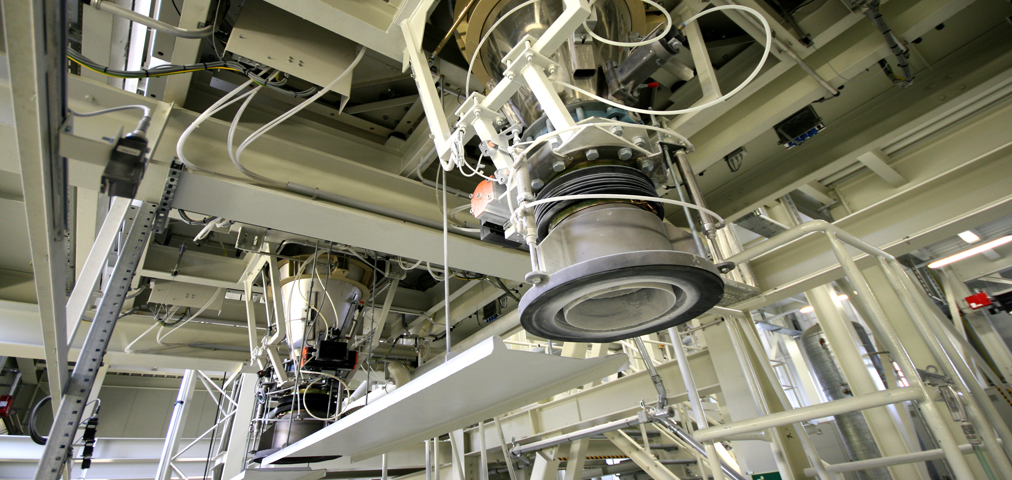

Batchbin is a modular system that represents the optimum solution for this problem. Kremsmueller implemented here a flexible metering system which optimally utilizes the existing space at the plant. A wide variety of powdered components are now processed in the production facility, down to gram precision.

All segments of a comprehensive electrical, instrumentation and control equipment installation, as well as the mechanical assembly, were supplied. The plant now contains 14 km of wiring. The control system includes 1,100 inputs and outputs, the level-measurement system of 15 large-capacity hoppers, and data acquisition from 12 scales.

A self-optimizing system was developed to ensure precise metering. The delivery and programming of the IT environment including touch panels, displays, and a series of software solutions rounded out the project. For example, a barcode system makes sure that all products can be tracked accurately.

This project was implemented in only 6 months – 6 months during which operations in the production facilities were never disturbed. The customer is now able to gain an optimal overview of production – changeovers to new products can be effected extremely quickly.

Find out more about this system at www.batchbin.com