Thin-film evaporator technologies from Kremsmueller

Safely separate and recycle material mixtures

Thermal separation processes are essential for the recovery of valuable ingredients from waste and old materials or the efficient extraction and further processing of raw material components.

Thin film evaporation reliably separates even the most difficult material mixtures, turns the components into valuable raw materials and is extremely versatile for

- Fibre and cellulose industry

- Environmental technology

- Chemical industry

- Beverage and food industry

- Sugar and starch industry

- Polymer industry and petrochemicals

Optimum raw material extraction from all material mixtures

At Kremsmueller, you get distillation, evaporation and drying systems that are precisely tailored to your area of application – with one contact person from the initial idea to the last screw.

Our thin-film evaporator technology comes into play when the processing of materials needs to be complete and clean.

With the know-how of Kremsmueller’s experts, equipment is created that extracts the maximum amount of raw materials from a wide variety of material mixtures.

This guarantees maximum efficiency.

The basic principle:

In a thin film evaporator, the liquid or viscous media run down the walls of a heated cylinder, where the more volatile components evaporate and are then condensed again.

Solids and less volatile substances remain behind. Kremsmueller’s specialised machines reliably separate even complicated mixtures of substances – thanks to a precisely coordinated apparatus design and the control of dwell time and temperature.

The result: You obtain the maximum amount of recyclable materials from your source material in the most efficient way.

Customized rotor systems for efficient evaporation

It is also extremely important to choose the right rotor system, which creates turbulence in the liquid inside the machine. This ensures a high level of heat transfer and prevents undesirable effects such as crystallisation or polymerisation.

- Rigid rotors: Areas of application primarily in the food industry

- Nacheil rotors, metallic or PTFE tipped: Generally used in the chemical industry and for higher viscosities

- Pendulum beater: for saline solutions

Tight schedule? Ask us for the fastest way!

We put your most important apparatus engineering projects in the fast lane! If your apparatus has to reach its destination on time, even with a short lead time, the Kremsmueller team picks up the pace – solution-orientated and cooperative.

Convincing advantages

Residue-free separation of mixtures of substances

Maximum recovery of recyclable materials

Preservation of the valuable ingredients through gentle evaporation

Safe and complete separation of components from various waste and used materials

Cost savings on disposal

Reduction of environmental pollution

Technology | Surface area | Heating temperature | Working pressure | Areas of application |

|---|---|---|---|---|

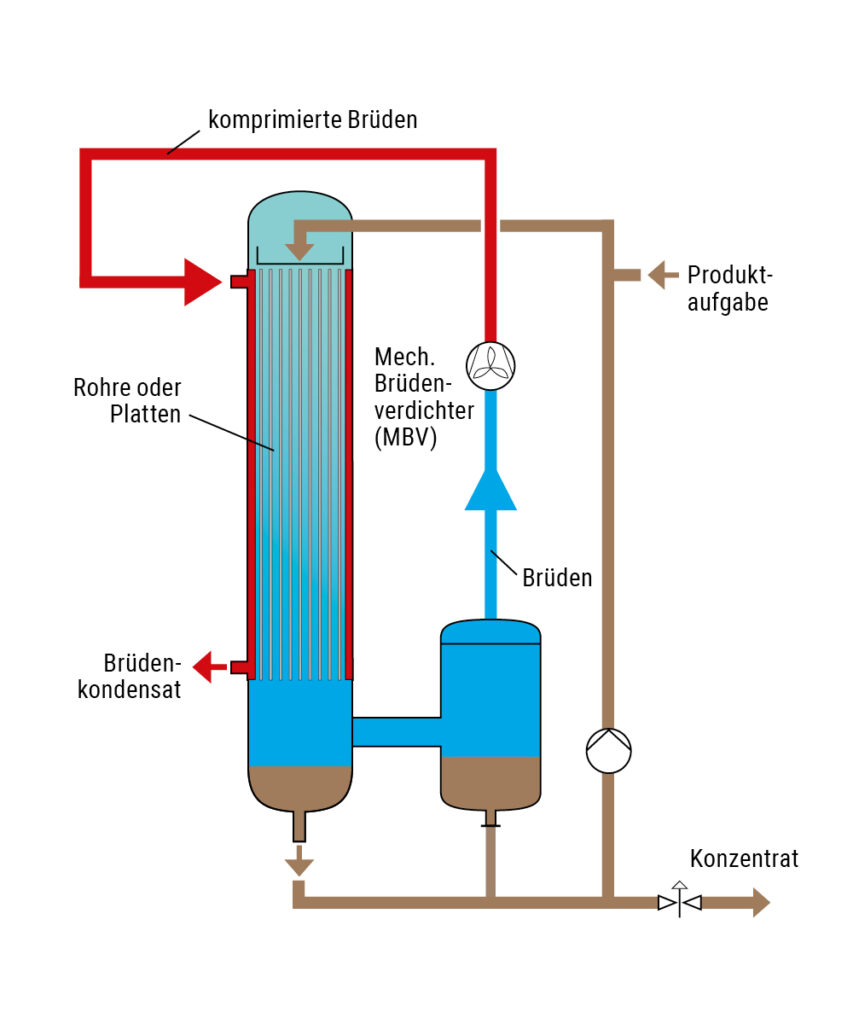

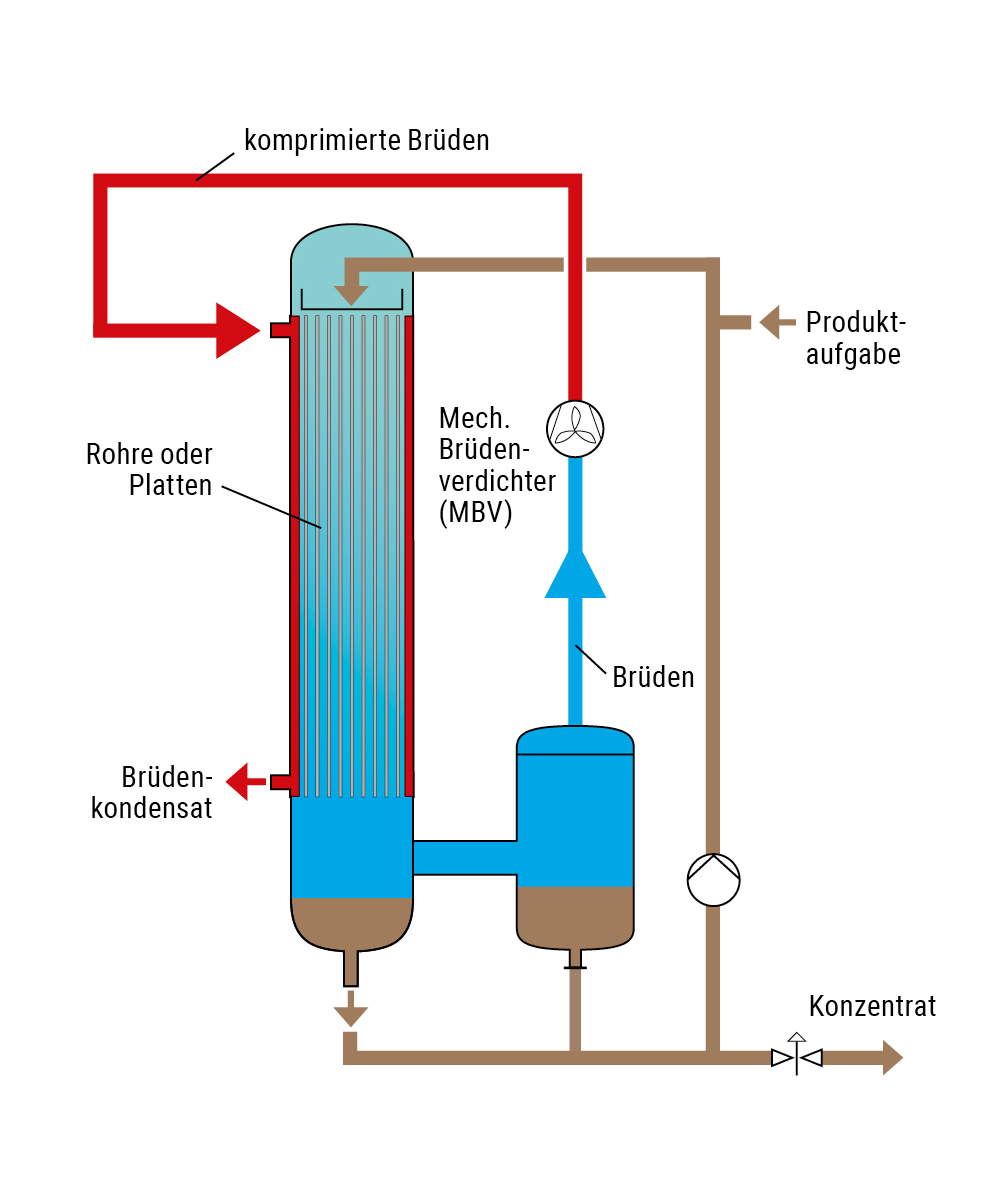

LIQUIFILM Falling film evaporator (FAFI) with thermal or mechanical vapour recompression (TBV or MBV) | up to 5,000 m² | up to approx. 200 °C | up to 10 mbar | Starch solutions, solvent recovery, black liquor, milk, caprolactam |

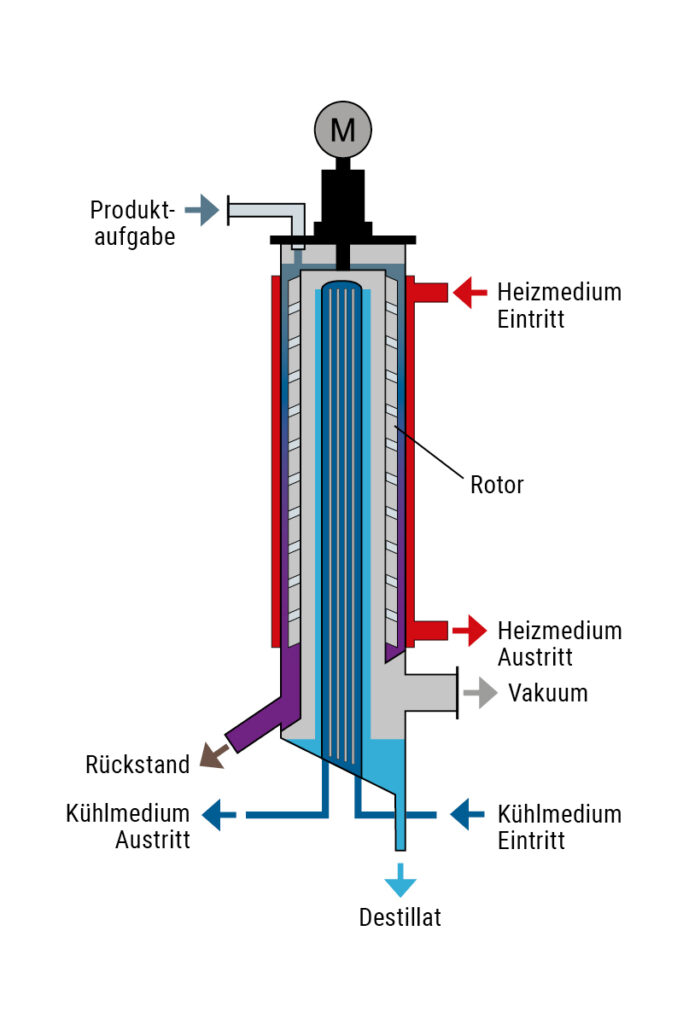

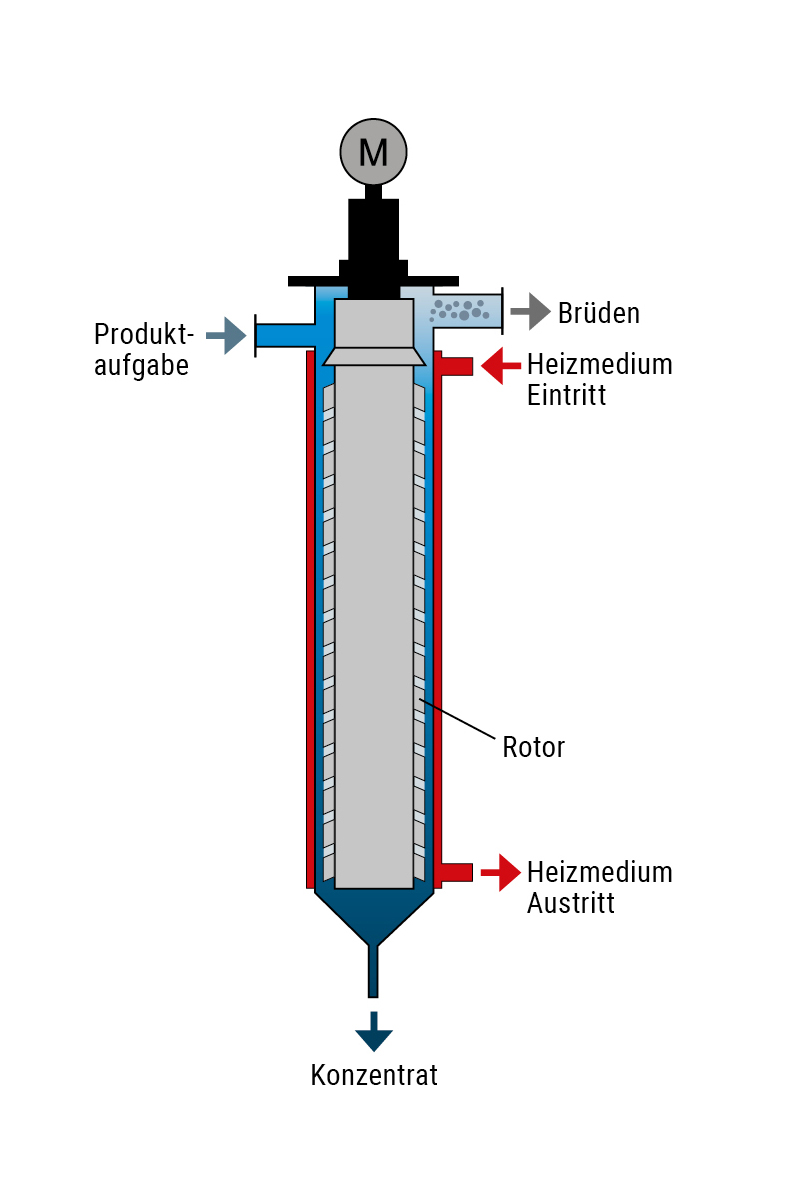

LIQUIVAP Thin film evaporator vertical | 0.1 to 60 m² | up to 500 °C | up to 1 mbar | Polymers, waxes, isocyanates, tall oil, fatty acids, oils, sorbitol, glycols, silicone oils |

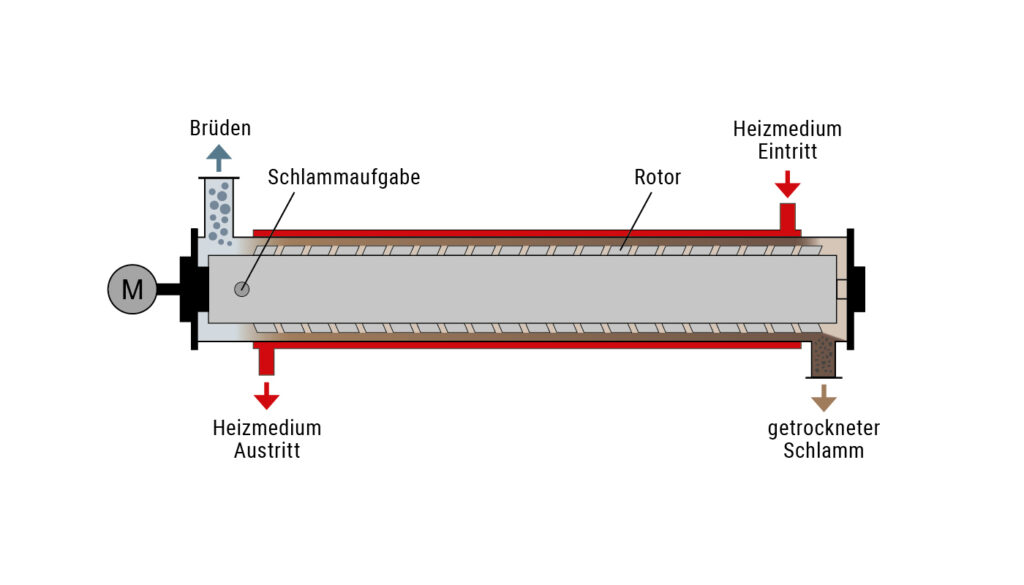

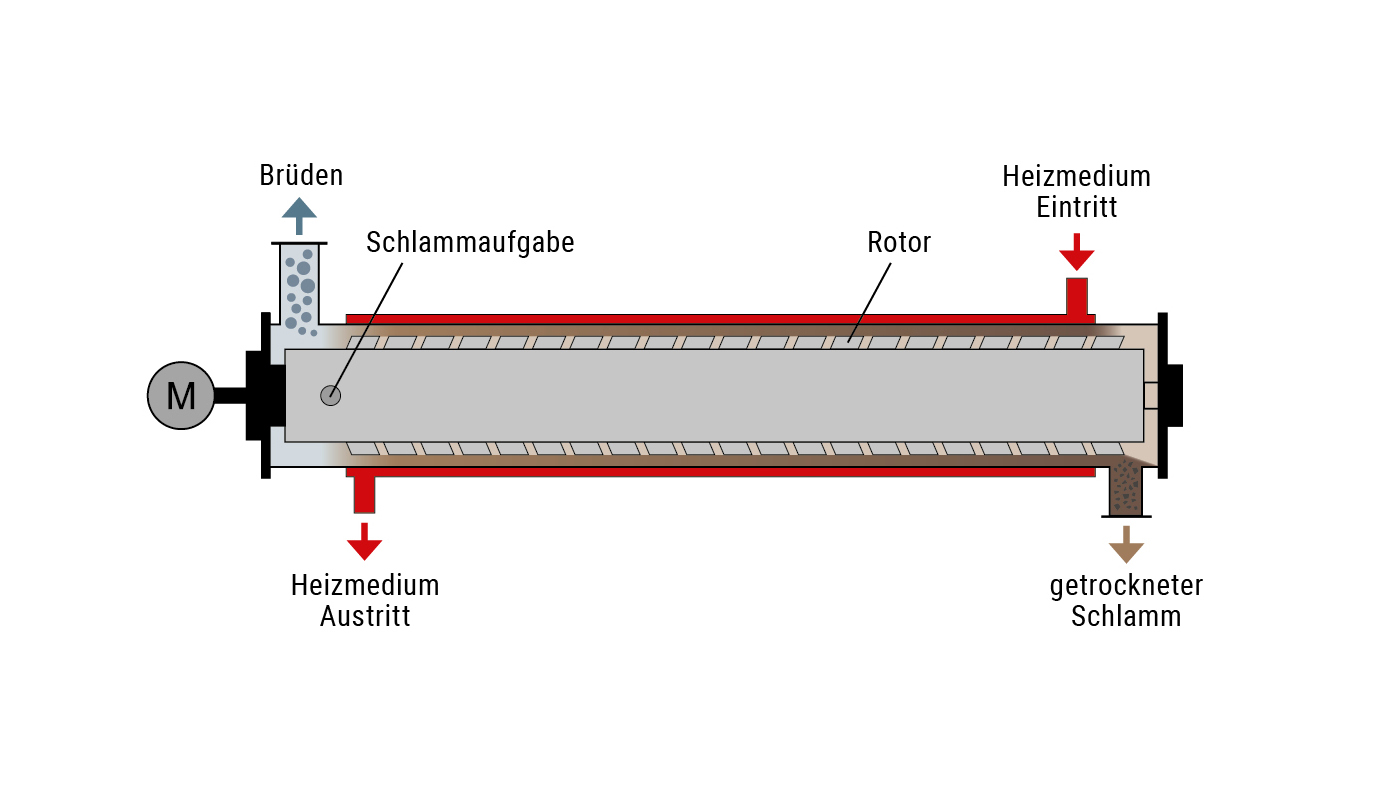

LIQUIDRY (V/H) Thin film dryer vertical and horizontal | 0.1 to 120 m² | up to 500 °C | up to 50 mbar | Municipal and industrial sludges, salt solutions, lecithin, glycerine, acids, suspensions and pastes |

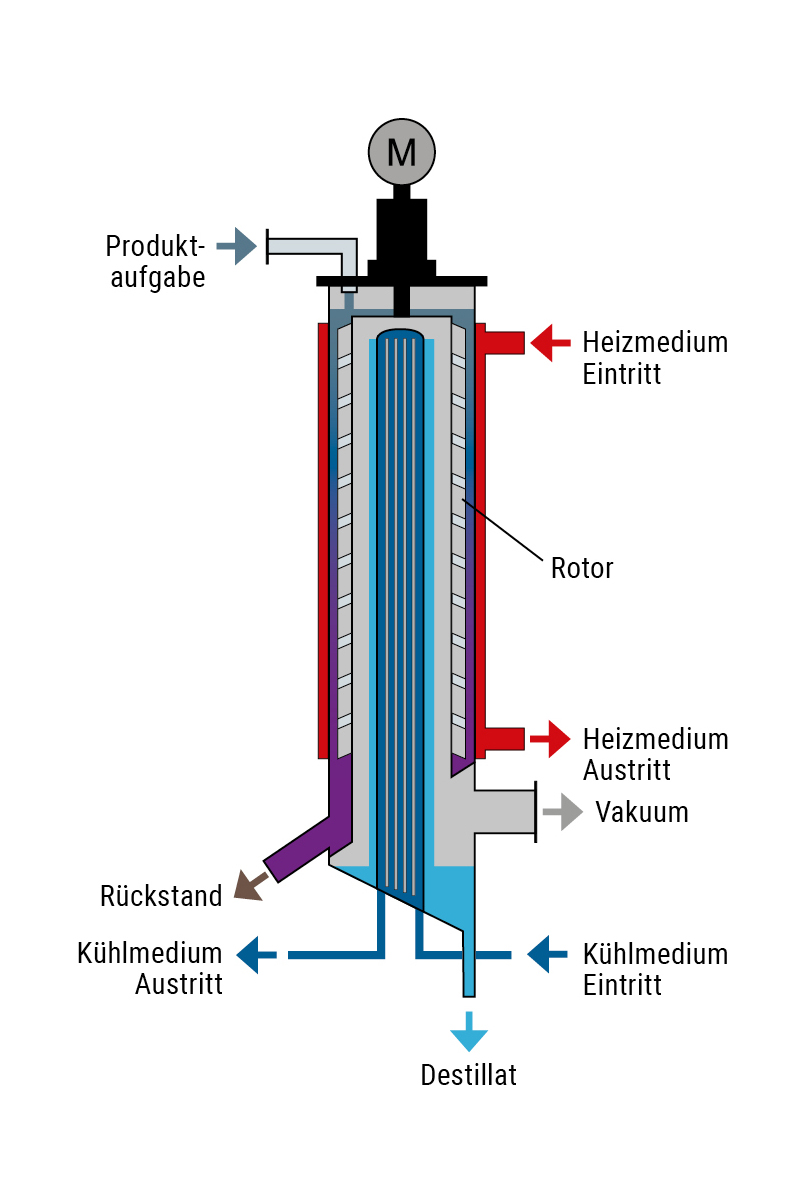

LIQUIMOL Short path vaporiser or molecular distillation | 0.1 to 60 m² | up to 450 °C | up to 0.001 mbar | Vitamins, isocyanates, fatty acids, biodiesel, lactic acid, monoglycerides |

- scroll

Thin-film evaporator technologies

With the right technology – falling film evaporator, thin film evaporator, thin film dryer or short path evaporator/molecular distillation – you can extract the maximum amount of recyclable materials from your source material with maximum efficiency.

Download folder

Download all relevant information on our thin-film technologies as a PDF.

LIQUIFILM

Falling film evaporators are particularly suitable for high evaporation rates, temperature-sensitive liquids, which can be evaporated very gently due to the low temperature difference and short process times.

LIQUIVAP

Enables gentle separation of liquid mixtures, e.g. greasy and oily components, oils and waxes with solid impurities or polymers.

LIQUIDRY

Sludge is a typical application for thin film dryers. In the course of further environmental requirements towards “zero liquid discharge” (ZLD), ever higher process temperature requirements are necessary. Kremsmueller is able to realise 500 °C and more for sludge drying in horizontal thin film dryers.

LIQUIMOL

Short path evaporators/molecular distillers are used, for example, to extract lactic acid via distillation and evaporation.

Lactic acid (polylactic acid, PLA) serves as a raw material for the production of bioplastics and replaces petroleum products.

If your machine has to be at its destination on time, even with a short lead time, the Kremsmueller team will get up to speed - solution-orientated and cooperative.

Why Kremsmueller?

- Because with us, you have one point of contact for the entire project, from the initial idea to the last screw. And we are also at your side for maintenance and servicing, dismantling and renovation. This complete package is unique on the market and means less planning work and interfaces for you, more security and adherence to deadlines

- Because we keep an eye on all aspects of your project - including planning, expert advice and forward-looking solutions for complex situations.

- Because we mean what we say: from project start to delivery date, from maintenance and repair to dismantling

- Because we are sustainable: from the use of renewable energies in production to responsibility for our employees and trusting, long-term relationships with our customers.

Head of Sales, Thin Film Evaporators

We process what you need

In thin-film evaporator construction, we process a wide range of materials that can withstand the highest loads, for example corrosion, pressure or temperature, according to our customers’ requirements.

One of the most modern machine parks in Europe and Kremsmueller specialists ensure unrivalled precision. Our numerous certifications vouch for our quality.

Your contact for thin-film technologies