Transportation at the Top Level

Batchbin supplies the complete conveying technology for a production plant

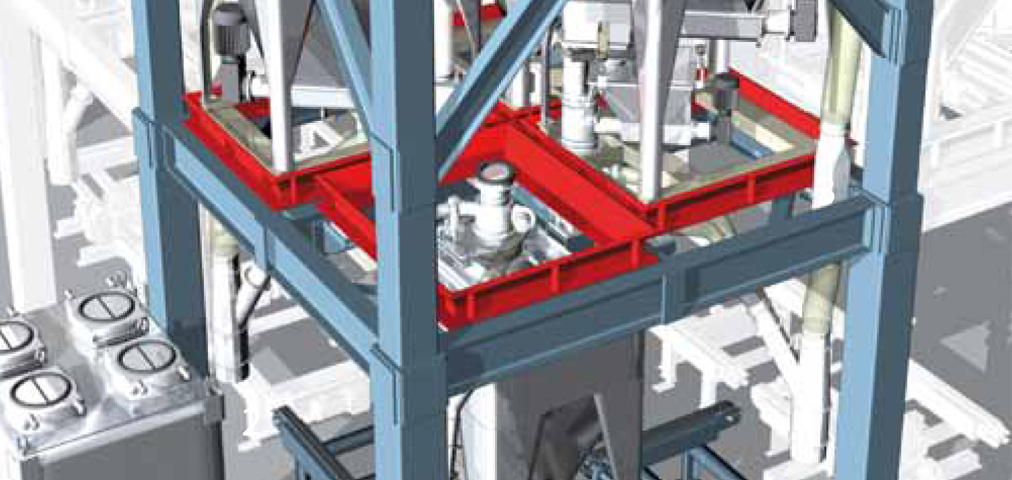

With the planning, supply and complete installation of the dosing technology for the production plant of an industrial floor manufacturer, Batchbin showed what is actually possible in the domain of powder dosing. The I&C experts of Kremsmueller took over the automation of the entire plant.

The problem facing the customer was practically tailor-made for Batchbin: Thanks to a large order, the industrial floor manufacturer had to expand his production plant. The installation of an additional 35-metre-high mixing tower, which is considered quite normal in the sector, would have meant huge rebuilding costs. By applying the Batchbin technology, the production plant requires a minimum amount of space.

For transporting the product components from the dosing system to the mixer and thereafter to the packing machine, the team installed a robo-tower. Thanks to this system, the transporting containers, which are called shuttles, can be moved not just vertically but horizontally as well.

From the mixer, which the Batchbin team integrated in the new plant, the product is moved downwards in the shuttles and transported to the packing machine. A simple and cost-saving solution.

Would you like to know more about the Batchbin technology? Click at the top right on Contact to directly reach the engineering team.

The problem facing the customer was practically tailor-made for Batchbin: Thanks to a large order, the industrial floor manufacturer had to expand his production plant. The installation of an additional 35-metre-high mixing tower, which is considered quite normal in the sector, would have meant huge rebuilding costs. By applying the Batchbin technology, the production plant requires a minimum amount of space.

For transporting the product components from the dosing system to the mixer and thereafter to the packing machine, the team installed a robo-tower. Thanks to this system, the transporting containers, which are called shuttles, can be moved not just vertically but horizontally as well.

From the mixer, which the Batchbin team integrated in the new plant, the product is moved downwards in the shuttles and transported to the packing machine. A simple and cost-saving solution.

Would you like to know more about the Batchbin technology? Click at the top right on Contact to directly reach the engineering team.