Three Divisions at Paper Mill Shutdown

Industrial Plant Construction, Apparatus and Tank Construction along with Pipeline Construction were involved in the conversion of the digester filling stations.

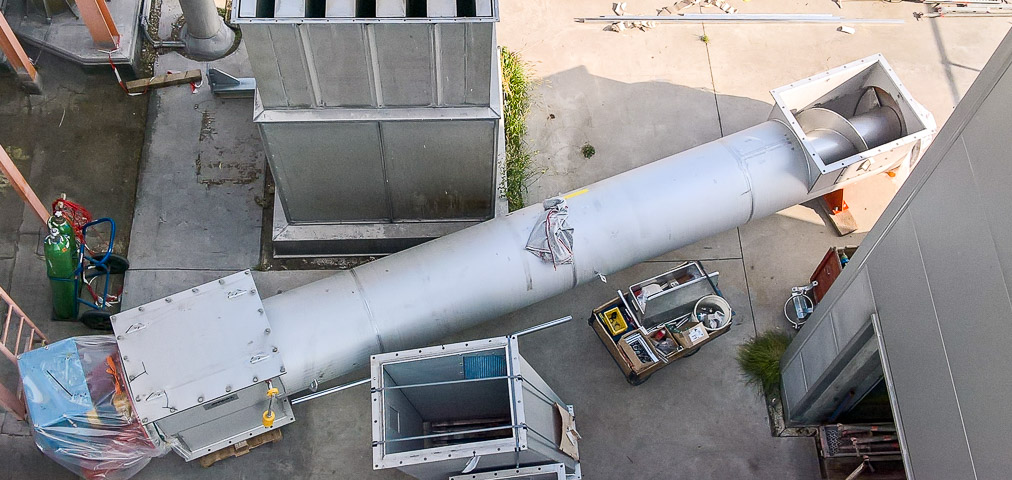

Kremsmüller received several commissions from Smurfit Kappa in Nettingsdorf. The Industrial Plant Construction, Apparatus and Tank Construction and Pipeline Construction departments worked closely together on the digester filling systems for pre-damping wood chips.

The plant engineering team was responsible for renewing the wood chip silo discharge. The new silo floor was delivered in three parts and subsequently assembled. In addition, the team installed two new discharge screws and a feed screw with drives. Replacing old screws with new ones had to be accomplished during a nine-day shutdown. During this period, the Tank Construction Division also exchanged the filters on four digesters. The work was completed on schedule thanks to excellent coordination and many years of experience in the paper industry.

The Pipeline Construction Division also contributed significantly to the overall project. It was entrusted with the entire process piping, a total of 1,300 metres in nominal widths DN 15 to DN 500, pump installation and the assembly of tanks and heat exchangers. Installing the flash tank with a lifting weight of around 18 tons was one of the many challenges facing the fitters. Numerous connection points had to be taken into account during the shutdown.

“As always, the Kremsmüller fitters involved in the conversion gave a phenomenal performance,” comments Robert Petroschinsky of the Planning Department at Smurfit Kappa Nettingsdorf.

The plant engineering team was responsible for renewing the wood chip silo discharge. The new silo floor was delivered in three parts and subsequently assembled. In addition, the team installed two new discharge screws and a feed screw with drives. Replacing old screws with new ones had to be accomplished during a nine-day shutdown. During this period, the Tank Construction Division also exchanged the filters on four digesters. The work was completed on schedule thanks to excellent coordination and many years of experience in the paper industry.

The Pipeline Construction Division also contributed significantly to the overall project. It was entrusted with the entire process piping, a total of 1,300 metres in nominal widths DN 15 to DN 500, pump installation and the assembly of tanks and heat exchangers. Installing the flash tank with a lifting weight of around 18 tons was one of the many challenges facing the fitters. Numerous connection points had to be taken into account during the shutdown.

“As always, the Kremsmüller fitters involved in the conversion gave a phenomenal performance,” comments Robert Petroschinsky of the Planning Department at Smurfit Kappa Nettingsdorf.