Supervision in a Chinese Refinery

Kremsmüller was commissioned with the design and supervision of a vapour accumulator and thus contributes to environmental protection.

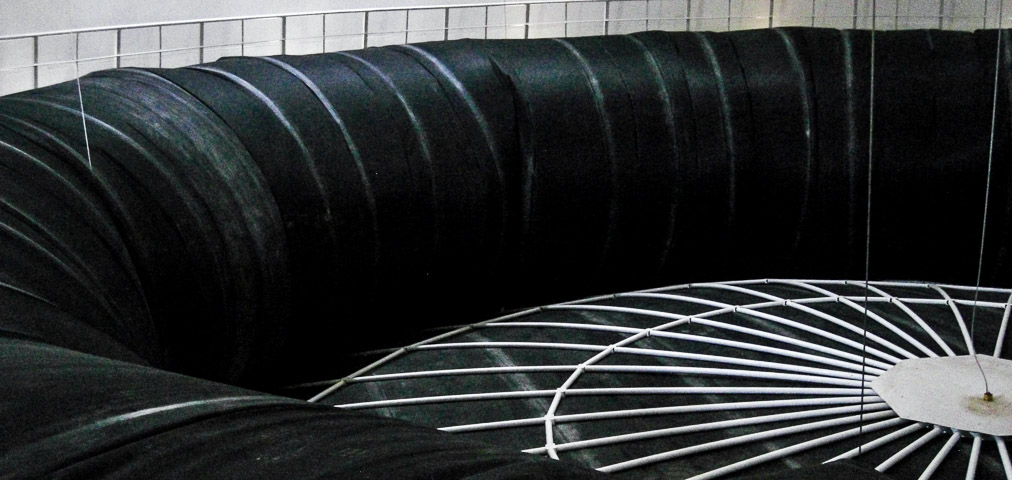

A Chinese refinery in Kunming commissioned Kremsmüller with a flat-bottom tank with a plastic diaphragm bladder for recovering petrol vapours. The 5,000m³ tank measures 18 meters in height, 22 meters in diameter and weighs around 20 tons.

In contrast to most other projects, the Apparatus and Tank Construction Department was not responsible for manufacturing the tank itself. Kremsmüller supplied the entire engineering as well as the core equipment for the diaphragm technology. In order to ensure the manufacturing process progressed flawlessly, two in-house tank construction experts were entrusted with on-site supervision. They were also in charge of the acceptance, test run and commissioning.

The flat-bottom tank makes a significant contribution to meeting strict environmental legislation. The harmful vapours can be temporarily stored and then converted back into liquid petrol, thus eliminating pollutant emissions.

Our experts will be happy to provide you with detailed information. Simply send an email request by clicking on Contact (letter symbol).

In contrast to most other projects, the Apparatus and Tank Construction Department was not responsible for manufacturing the tank itself. Kremsmüller supplied the entire engineering as well as the core equipment for the diaphragm technology. In order to ensure the manufacturing process progressed flawlessly, two in-house tank construction experts were entrusted with on-site supervision. They were also in charge of the acceptance, test run and commissioning.

The flat-bottom tank makes a significant contribution to meeting strict environmental legislation. The harmful vapours can be temporarily stored and then converted back into liquid petrol, thus eliminating pollutant emissions.

Our experts will be happy to provide you with detailed information. Simply send an email request by clicking on Contact (letter symbol).