Storage Tanks Designed to Withstand Earthquakes

From the initial idea to on-site assembly, everything originated from a single source and was undertaken in-house.

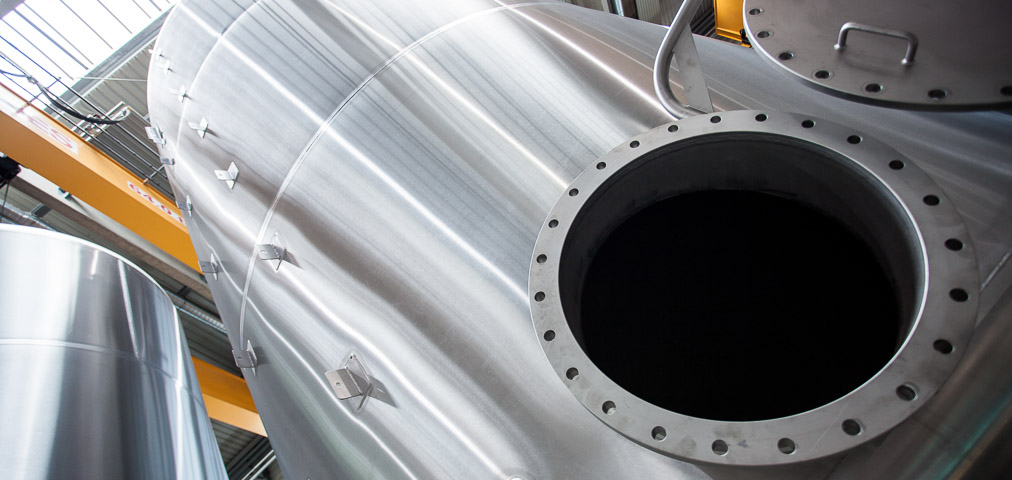

The company Hollu Systemhygiene modernised and expanded its production, requiring eight new storage tanks for alcohols. The prerequisite: the supplier should have the necessary expertise to provide an entire range of services from engineering and manufacturing through to transport and assembly – a project tailor-made for the “United Skills of Kremsmueller”. Based on the plans drawn up by us, five 30m³ storage tanks each with a diameter of 2.5m, and three 60m³ tanks, each with a diameter of 3.5m, were constructed. All the tanks were about 8m high.

Two facts make this venture special. Firstly, Zirl (near Innsbruck) is located in Austria’s highest earthquake zone 4. This meant that ground movements had to be taken into account in the calculations (with regard to lateral acceleration, etc.). The connection of the pipe feet to the tank had to be sufficiently dimensioned. The thickness of the lower base at 8 mm is twice as thick as normally required. Secondly, polished stainless steel was used for the tanks. Kremsmüller has rarely accommodated such shiny sheet metal in its production. Machine-polished material has a very even surface. Every scratch, even fingerprints, once visible are virtually irreversible. Great care and attention were therefore required when handling the material.

Using special transport the eight tanks were moved 300 km to Zirl. After lifting the tanks into place, special technology was used to prevent damage to the pre-sealed base. With the help of a modular air cushion transport system and not with conventional heavy-duty rollers, the tanks were shifted, placed in exactly the right position and then secured by means of special adhesive anchors.

“Getting everything from one source was a basic condition for Hollu. In addition, our modern machinery convinced them that we could also produce the tanks they required in an appealing quality. Ultimately, the customer was highly delighted with the clean workmanship á la Kremsmüller. It is possible that we will be on board again in the next expansion phase in one to two years from now,” enthuses the Kremsmüller project manager optimistically.

Walter Primus, Head of Technology at Hollu Systemhygiene: “During the entire course of the project we felt the support we received from sales and technology at Kremsmüller could not have been better!

Two facts make this venture special. Firstly, Zirl (near Innsbruck) is located in Austria’s highest earthquake zone 4. This meant that ground movements had to be taken into account in the calculations (with regard to lateral acceleration, etc.). The connection of the pipe feet to the tank had to be sufficiently dimensioned. The thickness of the lower base at 8 mm is twice as thick as normally required. Secondly, polished stainless steel was used for the tanks. Kremsmüller has rarely accommodated such shiny sheet metal in its production. Machine-polished material has a very even surface. Every scratch, even fingerprints, once visible are virtually irreversible. Great care and attention were therefore required when handling the material.

Using special transport the eight tanks were moved 300 km to Zirl. After lifting the tanks into place, special technology was used to prevent damage to the pre-sealed base. With the help of a modular air cushion transport system and not with conventional heavy-duty rollers, the tanks were shifted, placed in exactly the right position and then secured by means of special adhesive anchors.

“Getting everything from one source was a basic condition for Hollu. In addition, our modern machinery convinced them that we could also produce the tanks they required in an appealing quality. Ultimately, the customer was highly delighted with the clean workmanship á la Kremsmüller. It is possible that we will be on board again in the next expansion phase in one to two years from now,” enthuses the Kremsmüller project manager optimistically.

Walter Primus, Head of Technology at Hollu Systemhygiene: “During the entire course of the project we felt the support we received from sales and technology at Kremsmüller could not have been better!