Quality without any Compromises

Kremsmüller has completed a project to increase the rolling force in a Dutch steel mill.

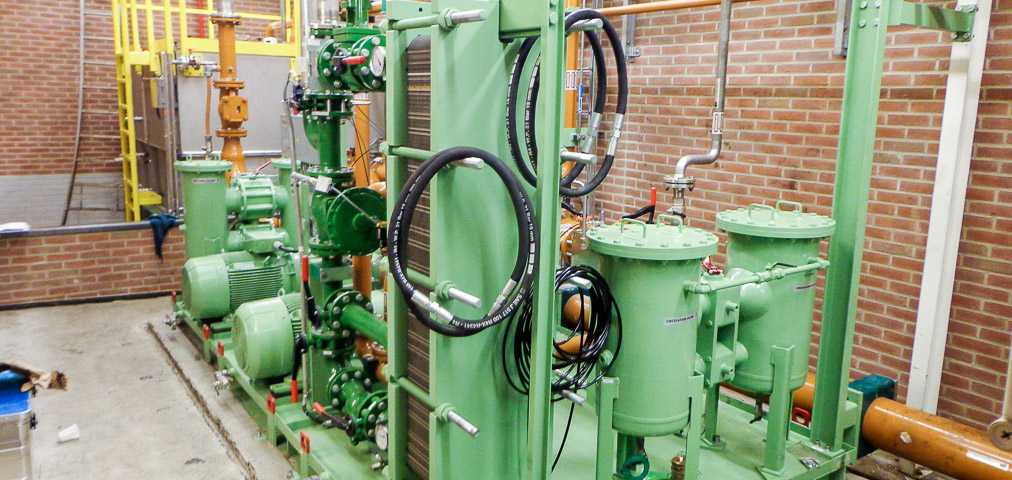

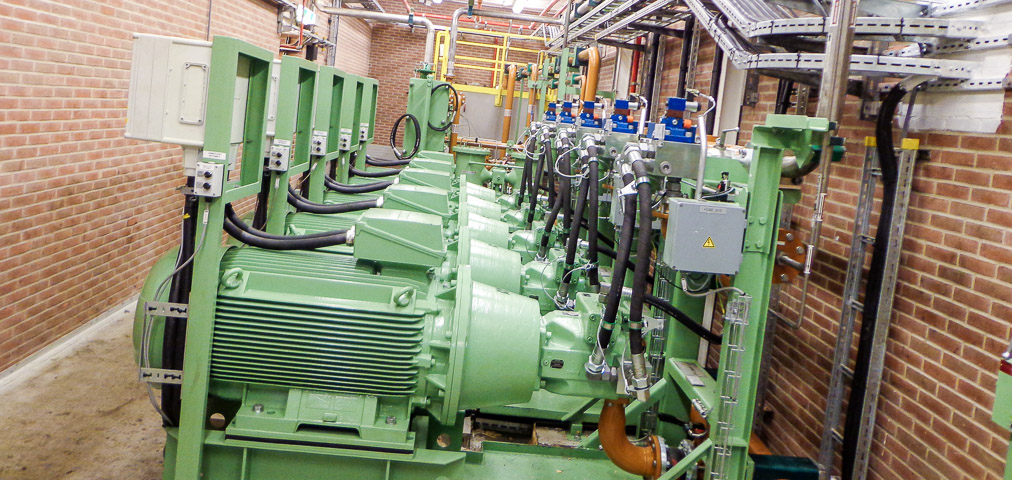

Kremsmüller was entrusted with the construction of the new hydraulic chamber in the factory cellar along with the piping to the roll stands. In order to be able to complete the tasks during the two-week shutdown period, the equipment and the main piping had to be pre-installed, flushed and tested. Following the downtime in late 2016, operations proceeded in rapid succession. The assembly team dismantled the old equipment on the roll stands and installed the new one.

After completion of one of the rolling stands, commissioning commenced immediately. The other four stands were processed in parallel. Despite a tight schedule and strict safety requirements, Kremsmüller accomplished the tasks on time and without any complications.

“Because a second Kremsmüller project was underway at the plant, synergies could be exploited. The customer demanded ‘high quality’ without any inconsistencies or compromises, and that’s exactly what we delivered,” explains the project manager in charge.

After completion of one of the rolling stands, commissioning commenced immediately. The other four stands were processed in parallel. Despite a tight schedule and strict safety requirements, Kremsmüller accomplished the tasks on time and without any complications.

“Because a second Kremsmüller project was underway at the plant, synergies could be exploited. The customer demanded ‘high quality’ without any inconsistencies or compromises, and that’s exactly what we delivered,” explains the project manager in charge.