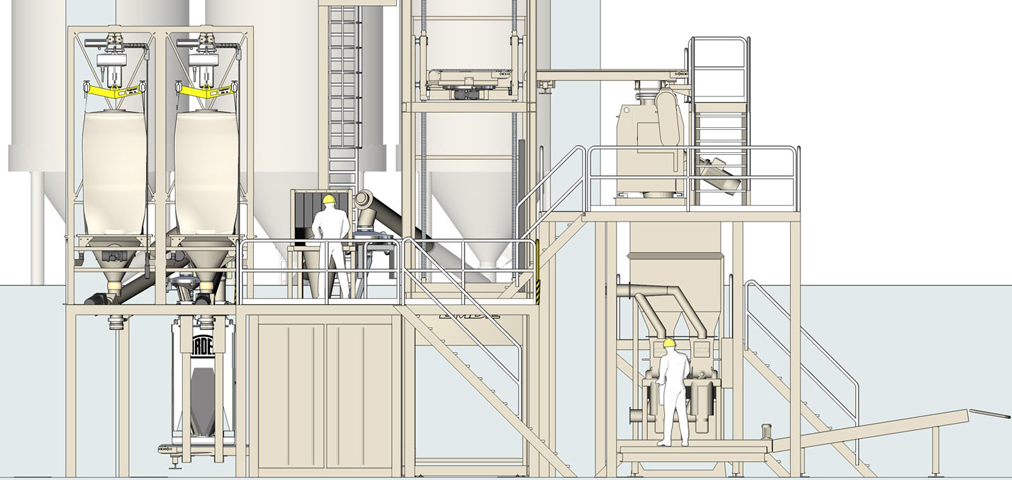

Batchbin: In action in Istanbul

Dosing technology for optimising the entry in a new market.

A manufacturer of chemical products used in the construction industry wishes to open new production facilities all over the world. With the technology from Batchbin, this step can be taken without any risk. The modular system can be easily integrated in existing plants and expanded in stages. The investment always remains overseeable.

The first dosing plant in this basic construction was commissioned this year in Istanbul. It outputs 10 batches per hour – that corresponds to 400 sacks containing 25kg finished product each. A tank with a volume of 1,200 l moves fully automatically over the chain conveyor and robot shuttle lift through the production shop. According to an exactly specified sequence, the components + 250g are dosed accurately into the shuttle. The ready batch is then emptied into a mixer, before the process starts all over again.

This fascinating modular technology is particularly suitable for fast entry in new markets – Depending on the wage levels and the budget, in a fully manual or even a highly automated version.

You can get more information on Batchbin here. You can reach an expert from Batchbin directly by clicking on "Contact".