Batchbin – customised

The perfect technical solution was found for modernising a conveying system

For this customer, a supplier of fire-resistant materials for the steel industry, Batchbin modernised the conveying system right from the mixer up to the filling station. The product to be transported is a highly sensitive mixture of fibres and corundum. Since its firmness makes the filling and emptying of the transport shuttle difficult, the Batchbin team came up with a customised solution.

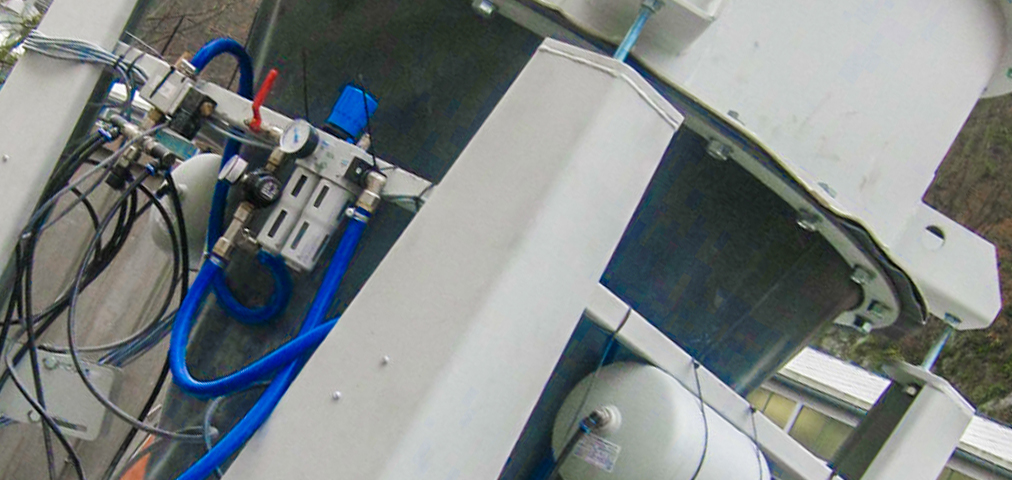

A conical transport shuttle made of rubber was developed. In its inside, the engineers installed four impact cylinders that move diagonally with respect to each other. At the filling station, the cylinders work against one another till the transport shuttle is completely empty. The modernised conveying system from the mixer to the filling station was made fully operational a short time ago.

The Batchbin dosing technology is based on a modular system. Batchbin systems can be customised to existing space conditions with little financial input or technical effort. Complicated modifications are not required. Batchbin is a part of the Kremsmueller group. Right from assembly to programming and automation, customers can place their trust during projects in the familiar, reassuring Kremsmueller quality.

Do you have questions about the project? You can reach the Batchbin team with a click on Contact.

Get to know more here batchbin.com

A conical transport shuttle made of rubber was developed. In its inside, the engineers installed four impact cylinders that move diagonally with respect to each other. At the filling station, the cylinders work against one another till the transport shuttle is completely empty. The modernised conveying system from the mixer to the filling station was made fully operational a short time ago.

The Batchbin dosing technology is based on a modular system. Batchbin systems can be customised to existing space conditions with little financial input or technical effort. Complicated modifications are not required. Batchbin is a part of the Kremsmueller group. Right from assembly to programming and automation, customers can place their trust during projects in the familiar, reassuring Kremsmueller quality.

Do you have questions about the project? You can reach the Batchbin team with a click on Contact.

Get to know more here batchbin.com