Technology Finds its Way into Production

High-precision mechanical engineering, complex processes, challenging special materials ? Kremsmüller is gaining a foothold in process technology.

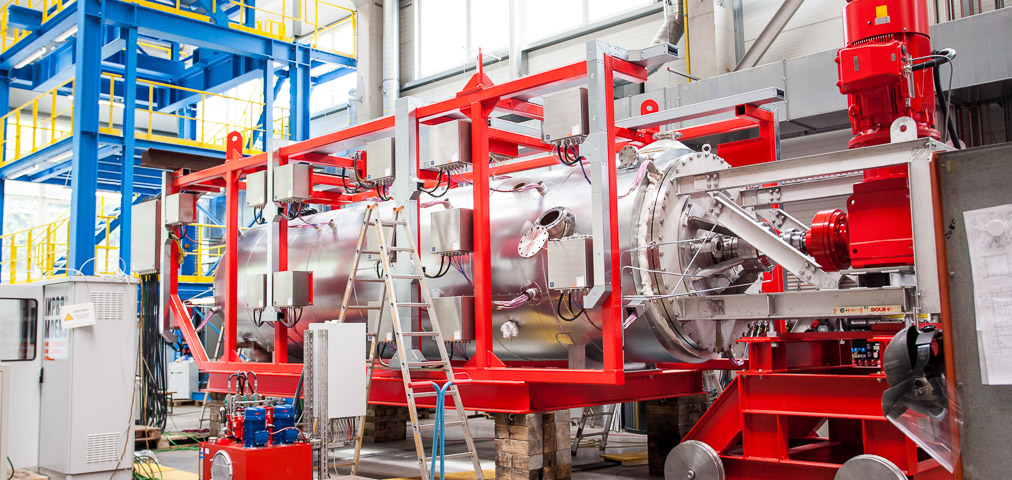

Kremsmüller is in prime position when it comes to process equipment engineering. In recent months, the requisite infrastructure has been created for this purpose. While Kremsmüller is optimally positioned in terms of electrical instrumentation and control technology, and automation technology, the adaptations for the new production steps have now been implemented in the production halls.

To this end, a special scaffold tower was built for the process equipment, enabling trial operations to be carried out in a vertical position. In a complex but necessary undertaking, the finished apparatus had to be dismantled again and the components lifted over the hall roof using a special crane and then assembled vertically with the utmost precision. The trial operation serves to guarantee the planned values. Only after this quality assurance is the apparatus ready for delivery.

Kremsmüller is breaking new ground in this segment. In order to be able to serve a multitude of industries, it is necessary to establish strong partnerships with engineering consultancies. In the field of thermal separation technology, as is the case with thin film evaporators, for example, we have built up our know-how in-house. Thus, in cooperation with the other departments of Kremsmüller it is possible to offer a unique complete package without any interfaces.

All aspects of evaporator technology, including process engineering, feasibility studies and pilot plants, are completely covered by experts at Kremsmüller. The result is already apparent ? the first projects have been successfully completed and further challenging projects are already in the pipeline.

If you would like to find out more about our technology division, simply click on Contact and you can reach our experts directly by email.

To this end, a special scaffold tower was built for the process equipment, enabling trial operations to be carried out in a vertical position. In a complex but necessary undertaking, the finished apparatus had to be dismantled again and the components lifted over the hall roof using a special crane and then assembled vertically with the utmost precision. The trial operation serves to guarantee the planned values. Only after this quality assurance is the apparatus ready for delivery.

Kremsmüller is breaking new ground in this segment. In order to be able to serve a multitude of industries, it is necessary to establish strong partnerships with engineering consultancies. In the field of thermal separation technology, as is the case with thin film evaporators, for example, we have built up our know-how in-house. Thus, in cooperation with the other departments of Kremsmüller it is possible to offer a unique complete package without any interfaces.

All aspects of evaporator technology, including process engineering, feasibility studies and pilot plants, are completely covered by experts at Kremsmüller. The result is already apparent ? the first projects have been successfully completed and further challenging projects are already in the pipeline.

If you would like to find out more about our technology division, simply click on Contact and you can reach our experts directly by email.