22 Tonnes of Precision Work

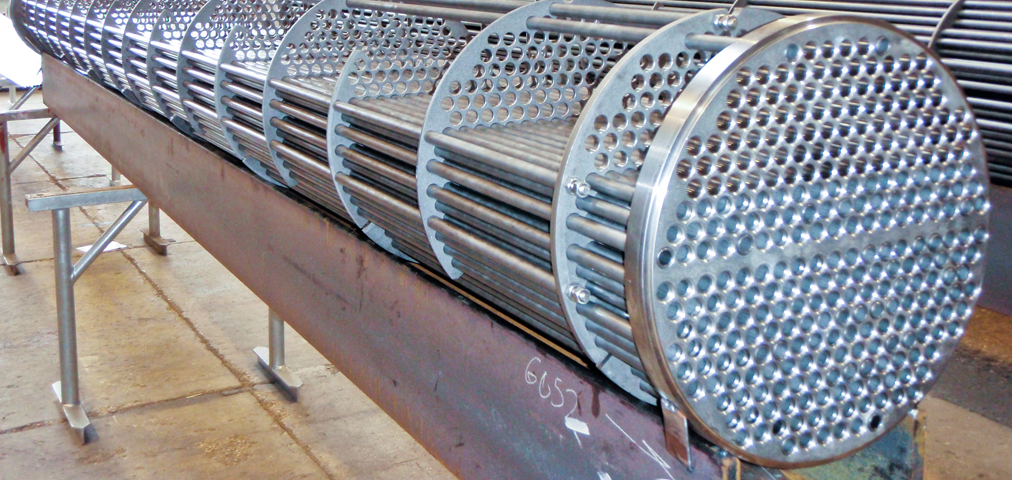

The experts from Kremsmueller manufactured heat exchangers for a gas-fired power plant.

A gas-fired power station to the north of Vienna was renovated in the course of a plant shutdown in September 2010. The customer entrusted Kremsmueller with the replacement of the heat exchanger. These apparatuses are used to cool the natural gas that has been heated owing to the pressure in the pipelines.

The challenge was in manufacturing the required tube bundles. No less than 300 tubes were welded per bundle. Orbital welding technology was used in the production for a constant quality of the welding work – this is a modern robot-supported process for the welding of tubes. A subsequent heat treatment then ensured the optimum component properties. Now, the customer can count on many years of reliable service from the new apparatuses.

Kremsmuelller planned, manufactured and assembled a total of six such gas heat exchangers.

Would you like to know more about the project? Click on Contact on the right, and you will directly reach our experts.